Sublimation t-shirt printing is a game-changer for anyone looking to create custom, long-lasting prints. This method allows you to transfer vibrant designs directly into the fabric, ensuring they won’t fade or crack. Perfect for businesses or personal projects, sublimation is quick and effective, producing professional results every time

In this guide, we’ll cover everything you need to know—from what materials to use, to the step-by-step process of bringing your designs to life on a t-shirt.

Let’s dive in and explore how easy and rewarding t-shirt printing sublimation can be!

How to do Sublimation T-Shirt Printing

What is Sublimation Printing?

Unlike traditional printing methods that lay ink on top of a surface, sublimation printing utilizes heat and pressure to transfer dye onto a compatible material permanently. Here’s the magic:

- Special Ink: Sublimation inks are unique in that they transform from a solid to a gas state when heated, bypassing the liquid phase.

- Heat and Pressure: A heat press applies high heat and pressure, causing the sublimation ink on the transfer paper to turn into gas.

- Material Absorption: The polyester fabric of the t-shirt acts like a sponge, absorbing the gaseous dye.

- Permanent Bonding: As the material cools, the dye solidifies, becoming permanently embedded within the fibers. This creates a full-color, vibrant image that becomes part of the t-shirt itself.

Advantages and Disadvantages

Advantages | Disadvantages |

|

|

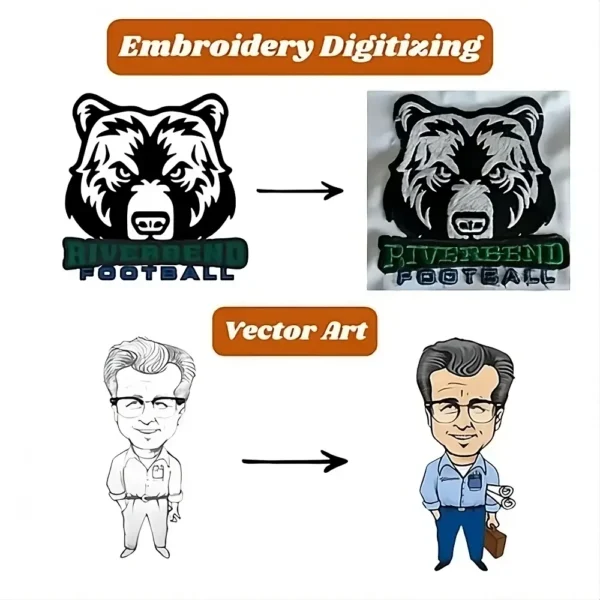

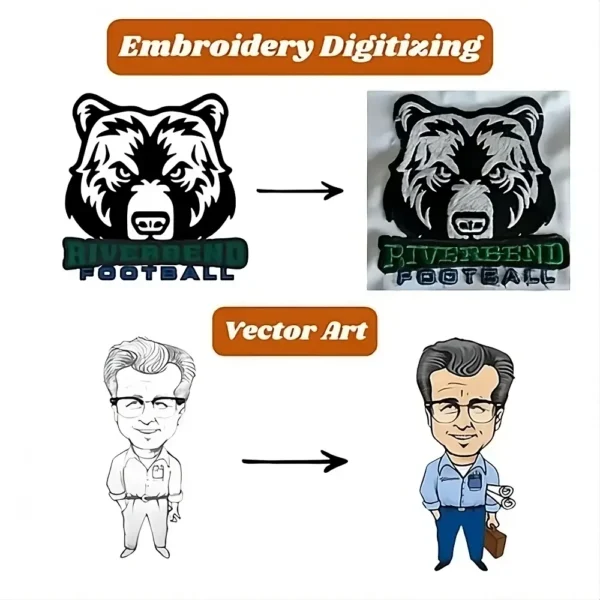

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Materials and Tools You Need for T Shirt Sublimation Printing

It allows you to create vibrant, full-color designs on polyester t-shirts. To get started, you’ll need a few key materials and tools.

- Sublimation Printer

- Sublimation Ink

- Heat Press Machine

- Sublimation Paper

- Polyester T-Shirts

- Heat-Resistant Tape

- Protective Paper (e.g., butcher paper)

- Design Software (e.g., Adobe Illustrator, CorelDRAW)

- Scissors or Cutting Tools

- Ruler or Measuring Tape

- Gloves (for handling hot materials)

- Lint Roller (for cleaning fabric)

1. Sublimation Printer

For dye sublimation T-shirt printing, it’s essential to use printers specifically designed for sublimation, such as the Epson SureColor series or Sawgrass Virtuoso. These printers are optimized for sublimation inks, ensuring high-quality prints with accurate colors and details.

2. Sublimation Ink

Using high-quality sublimation inks from reputable brands like Sawgrass or Epson is important. Quality inks produce vibrant colors and better durability, ensuring that prints withstand washing and wear over time.

3. Heat Press Machine

A reliable heat press, such as a clamshell or swing-away model from brands like Hotronix or Geo Knight, is crucial. Consistent and even heat application is key to successful sublimation, and quality machines provide better control over temperature and pressure.

4. Sublimation Paper

Choosing high-release sublimation paper, such as TexPrint or A-SUB, allows for better ink transfer during the heat press process. This results in sharper and more vibrant prints on the T-shirts.

5. Polyester T-Shirts

For the best sublimation results, it’s recommended to use 100% polyester or polyester-blend shirts from brands like Bella+Canvas or Gildan. Sublimation works best on synthetic fibers like polyester, allowing the ink to bond effectively for long-lasting prints.

6. Heat-Resistant Tape

High-temperature tape, such as Pro Tapes Pro-Gaff, is used to secure the design during the heat transfer process without melting or leaving residue on the fabric.

7. Protective Paper (e.g., butcher paper)

Uncoated butcher paper or parchment paper serves as a protective layer to prevent ink from bleeding onto the heat press and helps protect the fabric during the transfer process.

8. Design Software (e.g., Adobe Illustrator, CorelDRAW)

Professional design software that supports vector graphics is essential for creating precise designs. Programs like Adobe Illustrator or CorelDRAW enable accurate design creation and manipulation, resulting in high-quality sublimation prints.

9. Scissors or Cutting Tools

Precision scissors or a rotary cutter should be used to ensure clean cuts for your transfer designs. Clean edges help achieve a professional finish when applied to the fabric.

10. Ruler or Measuring Tape

Using a metal ruler or flexible measuring tape allows for accurate measurements, which are critical for proper design placement on the garment.

11. Gloves (for handling hot materials)

Heat-resistant gloves, such as those made from silicone or aramid fibers, protect your hands from burns when handling hot materials after pressing.

12. Lint Roller (for cleaning fabric)

Using a lint roller with sticky sheets helps remove debris from fabrics before printing. A clean surface ensures a flawless print by preventing dust and lint from interfering with the transfer process.

Step-by-Step Process for Sublimation T-Shirt Printing

Follow these steps to successfully print your design onto a polyester t-shirt using a sublimation printer for t-shirts.

Step 1: Design Preparation

Create or select your desired design using graphic design software. Mirror the design to ensure it appears correctly when transferred. If you have a low-quality image and need to improve its resolution, you can have it vectorized by us at ZDigitizing. We offer this service at the most affordable rates, ensuring high-quality results that are perfect for sublimation printing.

Step 2: Printing on Transfer Paper

Load your t-shirts with sublimation ink and transfer paper. Print the mirrored design onto the transfer paper using the highest quality settings.

Step 3: Substrate Preparation

Ensure the polyester t-shirt is clean and wrinkle-free. Use a lint roller to remove any debris. Pre-press the shirt for about 10-15 seconds to eliminate moisture and wrinkles.

Step 4: Heat Press Setup

Preheat your heat press to the recommended temperature, typically between 385°F and 400°F (196°C to 204°C). Place a piece of protective paper inside the shirt to prevent ink from bleeding through.

Step 5: Positioning the Design

Lay the printed transfer paper face down on the shirt, aligning it properly. Secure it with heat-resistant tape if necessary to prevent movement during pressing.

Step 6: Heat Press Application

Close the heat press, applying consistent pressure for about 45-60 seconds. Ensure that the heat and pressure are evenly distributed for optimal ink transfer.

Step 7: Cooling and Removal

Once the pressing time is complete, carefully open the heat press and remove the shirt. Allow the shirt to cool completely before gently peeling off the transfer paper. This helps set the ink properly.

Step 8: Final Touches

Inspect the finished product for any imperfections. Your t shirt printing sublimation process is now complete, and the shirt is ready for wear or sale!

Common Challenges and Solutions in Sublimation T-Shirt Printing

In t shirt printing sublimation, various challenges may arise, but with the right solutions, you can ensure high-quality prints.

1. Dull Colors

Challenge: Transfer prints appear lackluster.

Solution: Ensure you are using the correct side of the sublimation paper for printing and optimize color settings in your software. High-quality sublimation inks and papers are essential for vibrant results.

2. Ghosting

Challenge: Shadowy images or double prints.

Solution: Secure the transfer paper using heat-resistant tape to prevent movement during pressing. Remove the transfer paper immediately after pressing to minimize ghosting.

3. Incompatible Materials

Challenge: Printing on unsuitable substrates like 100% cotton.

Solution: Always use products with a high polyester content (preferably 100% polyester) for best results. Avoid dark fabrics unless using a white base layer.

4. Ink Bleeding

Challenge: Ink spreads beyond the intended design edges.

Solution: Protect your heat press with Teflon sheets and adjust pressure settings to ensure that the application is even without excess ink.

5. Small Dots or Blotches

Challenge: Small dots appear on the finished product.

Solution: Pre-press substrates to remove moisture before printing, which helps achieve a clean transfer.

Caring for Your Sublimated T-Shirts

Sublimated t-shirts offer vibrant, long-lasting designs, but proper care is essential to maintain their quality. Here’s how to keep your sublimated shirts looking their best:

Washing

- Turn the shirt inside out. This protects the design from abrasion during washing.

- Use cold water and a gentle cycle. Hot water can cause colors to bleed or fade.

- Opt for a mild detergent. Harsh detergents can damage the ink.

- Skip the fabric softener. It can leave a film that dulls the design.

- Wash with similar colors to avoid dye transfer.

- Remove the shirt promptly after the wash cycle to prevent wrinkles and setting of any stains.

Drying

- Hang drying is highly recommended. This minimizes shrinkage and wrinkling.

- If using a dryer, choose a low heat or tumble dry low setting. High heat can damage the fabric and design.

- Avoid drying for extended periods.

Ironing (if necessary)

- Use a cool iron setting only.

- Turn the shirt inside out before ironing.

- Avoid ironing directly on the design. Place a thin cloth between the iron and the design.

General Care

- Avoid harsh chemicals like bleach, which can damage the design and fabric.

- Don’t dry clean your sublimated shirts.

- Store your shirts in a cool, dry place away from direct sunlight. Excessive heat and light exposure can cause fading over time.

By following these simple care tips, you can extend the life of your sublimated t-shirts and enjoy their vibrant designs for years to come.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Conclusion: Ready to Start Sublimation T-Shirt Printing!

It is an excellent choice for creating vibrant, long-lasting designs that won’t fade or crack over time. Whether you’re printing for personal use or business, this method delivers professional results with minimal effort. By following the right steps and using the proper materials, you can easily bring your creative ideas to life.

If you’re looking for high-quality vector designs to use in your sublimation printing, our vectorization services at ZDigitizing are here to help. We offer fast turnaround times, affordable pricing, and guaranteed high-quality results. Plus, as a first-time customer, you’ll enjoy a 50% discount on your order.

Let us help you create the perfect design for your next project!

FAQs

The Epson SureColor F570 is highly regarded as one of the best sublimation printers for t-shirts, offering excellent print quality and efficiency for both beginners and professionals.

To use a printer for t-shirts, print your design on sublimation paper, place it face down on the polyester t-shirt, and use a heat press to transfer the ink onto the fabric.

Sublimation prints on t-shirts can last for years without fading, peeling, or cracking if properly cared for, maintaining vibrancy even after multiple washes.