If we talk about sublimated prints method, the same sublimation process it’s the transfer of ink on the fabric by the mentioned process. Design is being transferred using heat and ink.

But you will be confused about the opposite process as we talked about earlier. So the opposite of sublimation is deposition or de-sublimation.

Tried And Tested Tips For Making Sublimated Prints

What is sublimated prints:

Making Sublimated Prints Before getting to the concept of sublimated prints mark, first I am going to explain about the Sublimated Prints process. In scientific terms, the transition of any substance from the solid to gas state is known as sublimation without converting into a liquid state. In this state, only change occurs in the physical state. Meanwhile, the chemical composition remains constant.

In this term, the transition occurs from gas to solid without entering a liquid state. For instance, in the process of frosting, air directly freezes without going through the liquid phase.

Are Sublimation and heat transfer the same?

We can say that both are similar in the way that ink is being transferred on the fabric, but the difference is that; when a heat press transfer design makes a layer on the fabric but the sublimation mark transfers the embroidery design on the fabric, and design becomes the part of the fabric.

Materials required for sublimated prints:

The sublimated prints process is quite costly; the equipment is expensive too. But if you want quality content, then doing a good investment is recommended in this case.

Sublimation Paper:

You can use some other transfer papers too, but sublimation paper is designed to adjust the right pressure and temperature, so if you want good quality work without any change, you must buy it.

Computer/ laptop and RIP software:

If you have bought a sublimation printer, then it must include sublimated prints software. But you can purchase the software on your random PCs too.

Cutting Device:

It’s required to cut the transfer paper exactly like the design.

Heat press:

The purpose of heat press in sublimated prints is to transfer the design from sublimation/transfer paper to the material. By using this, the design will resist removing or fading on the material.

So after the above debate, the next question that comes to mind is how to perform the sublimated prints mark. Here are some steps to explain to you about the process of doing sublimated prints mark.

- First of all, select your design and print it on the special transfer paper by sublimation printer. Select the material on which you want to transfer design. To keep in mind that sublimation mark is greatly affected by the background, the right background choice is compulsory in the process.

- Place the transfer paper in the exact position where you want to print the design. In this step, keep in mind ink is still in the solid-state.

- Apply a heat press on the design printed on transfer paper. The main factors which affect the printings are pressure, temperature, and time, which always have different scales for different materials and prints.

- By applying heat-press, inks turn to gas due to the heat and pressure and combine with fabric. Hence the design is permanently printed on the fabric.

Little instructions are to be followed for a better quality print in other materials like plastics, PVC, or mugs.

Need/Benefits of sublimated prints:

If you want full creative and unique prints with a fast process, sublimated prints would be best. For simple, proper colored, quick and creative printing, sublimation mark is always recommended. Ideal for hoodies, t-shirts, and socks, hence gives its best to polyester stuff.

It might be more costly than other printing techniques, but the results it gives are always amazing. It generates a clear and bright picture of the material, which stays on the material even after several years of use. It cannot be peeled nor faded.

Why not use sublimated prints:

Sublimation mark is not suitable for all types of fabrics, especially if the fabric is 100 percent cotton, silk, and some other pure stuff. Another reason is its cost, so people rely on screen printing or heat press printing. Sublimation is often printed on white materials, so if somehow the design doesn’t reach the material, it will remain white on that part.

Conclusion:

Everything has its benefits, the same in the case sublimated prints is the most secure print which does not fade nor go out of fashion. Depending on your choice, you can enjoy the clear and vibrant prints on the materials.

Frequently Asked Questions

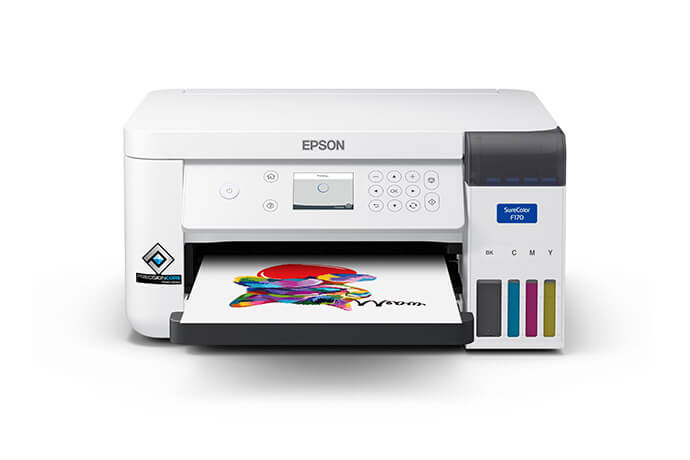

For sublimation print, you would need the following: 1. Sublimation-ready printer – you can either utilize a printer designed and produced for sublimation, or you could convert an already existing ink jet printer to support sublimation. 2. Sublimation paper – there are many kinds of sublimation paper out there. We would suggest the brand A-sub. 3. Heat press – you would need a heat press to transfer the design. Ensure to get a heat press that has the minimum size requirements for your designs and transfers. 4. Design software – You would need something to design your transfers with.

Sadly, no you cannot do sublimation printing at home. You want special dyes to print on the paper and not every printer play well with them. The majority of printers use the thermal or head method which would brake the sublimation dye right in the paper. As sublimation printing is transferring particular or sublimation dyes to a transfer sheet that then are imprinted or sublimated into textiles or other material by adding heat. The ink infuses in the shirt, material, mug, bag, phone case, etc, and makes a faultless design from seam to seam when high temperatures are added.

There are many options when it comes to choosing a design software for sublimation. Let us discuss some of the software you could use for sublimation: If you purchase a sawgrass virtuoso printer, you get a free design software suite called the creative studio. The 2 most popular sawgrass virtuoso printers are the SG500 and the SG1000. The second one is photoshop, the best software for your particular needs and requirement. But you might not be interested in the monthly subscription cost for the adobe suite. Don’t worry there are other alternatives, most notable GIMP. Eventually, you want to use software that enables you to manipulate the color profiles of your prints and enables you to design the way you want.

Sublimation printing is amazing for fine lines and details and is no doubt one of the finest methods for all-over printing. With low setup costs, it is best for small businesses, and the printing is so close to permanent that it is quite unbeatable. But it is not amazing for natural materials, requiring eighty percent poly-blends, and the white areas are left unprinted which could be challenging if you want to print on dark color materials.