Finding the right heat press doesn’t have to be complicated! Think of it like choosing the perfect tool to bring your creative ideas to life. Whether you’re designing custom t-shirts or working on unique projects, the right machine can make all the difference. This guide is here to simplify the process for you. From understanding the types of heat presses to exploring essential features, we’ll cover everything you need to know.

No matter your experience level, you’ll discover how to choose a heat press that fits your goals and budget. Ready to make an informed choice? Let’s get started!

How to Choose the Right Heat Press

Why Do You Need a Heat Press?

A heat press is a machine that uses both heat and pressure to permanently transfer your design onto various materials, like garments or blank items. Whether you’re working with heat transfer vinyl, sublimation printing, heat transfer paper, or white toner transfers, a quality heat press is essential for creating custom items.

You might wonder, “Can’t I just use a regular home iron?” Well, not really.

If you’re serious about selling your products and building a business, an iron won’t cut it. While you can technically use an iron for heat transfer vinyl, it’s hard to achieve consistent pressure, and the results may not last as long as those made with a heat press.

Plus, some methods, like white toner transfers and sublimation, simply can’t be done with a home iron, limiting what you can create.

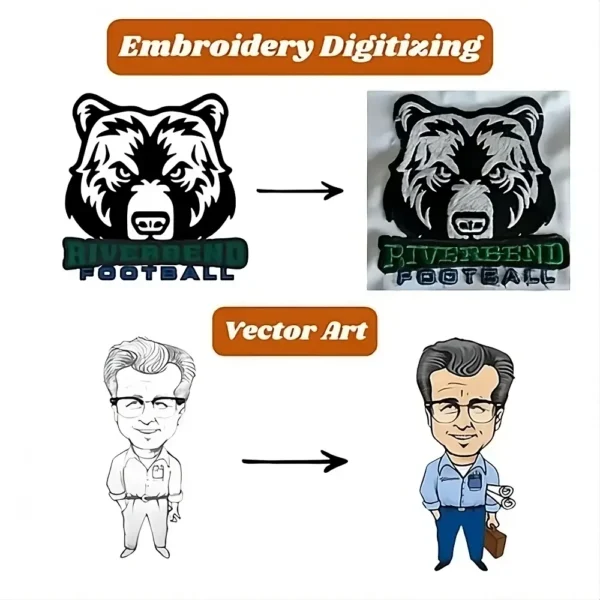

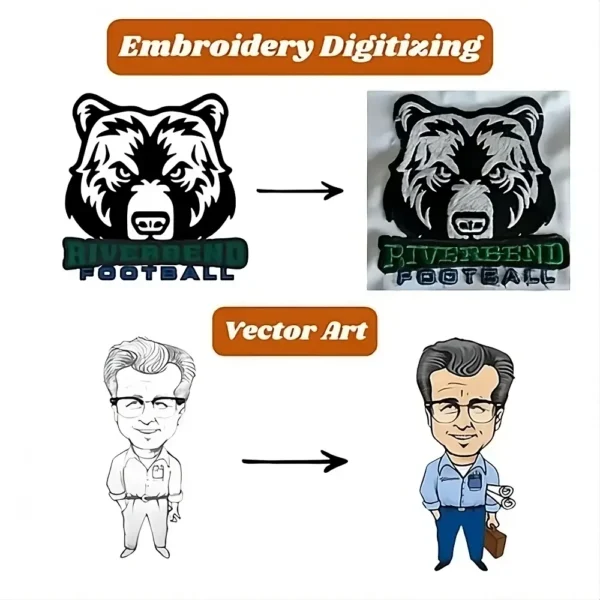

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Types of Heat Press Machines

Choosing the right heat press is essential for achieving professional results in your projects. Here’s a breakdown of the various types of heat machines to help you make an informed decision.

- Clamshell Heat Press

- Swing-Away Heat Press

- Draw Heat Press

- Handheld Heat Press

- Specialty Presses

1. Clamshell Heat Press

Clamshell heat presses are designed with a top platen that opens like a clamshell. This type is popular for its compact design, making it suitable for small workspaces. It is easy to operate, allowing users to quickly load and press garments. Clamshell presses are ideal for beginners and are commonly used for t-shirts, bags, and other flat items.

2. Swing-Away Heat Press

Swing-away heat presses feature a top platen that swings away from the bottom platen, providing full access to the workspace. This design allows for better visibility and easier placement of materials. The swing-away feature also helps to prevent accidental burns, making it a safer option for users. These presses are versatile and can be used for various applications, including thicker materials.

3. Draw Heat Press

Draw heat presses have a unique design where the bottom platen can be pulled out like a drawer. This allows for easy loading and unloading of garments without the risk of burns from the heated top platen. Draw presses are particularly useful for larger items or when working with multiple layers, as they provide ample space to maneuver.

4. Handheld Heat Press

Handheld heat presses are portable devices that allow users to apply heat and pressure manually. They are ideal for small projects or on-the-go applications, such as customizing items at events or fairs. While they may offer a different level of consistency than larger machines, they are convenient for quick touch-ups or small-scale operations.

5. Specialty Presses

Specialty heat presses are designed for specific applications or materials, such as cap presses for hats, mug presses for cups, and plate presses for plates or other curved items. These machines often come with unique features tailored to their specific use cases, allowing for high-quality results on specialized products.

Factors to Consider When Choosing the Right Heat Press

You might be wondering, “Which heat press is the best?”. The answer depends on what you need and like. With so many choices out there, it can get confusing.

But don’t worry! We’ll help you figure it out.

There are different heat presses for different things, like hats, mugs, and labels. Here, we’ll talk about how to choose the right heat press for shirts and other flat items because these are very popular and versatile.

Let’s see what you should think about when picking your first (or next) heat press!

- Temperature Consistency

- Pressure Adjustment

- Timer and Digital Controls

- Platen Size and Customization

- Manufacturer Reputation

- Warranty and Service Options

- Loading and Accessibility

- Budget Considerations

1. Temperature Consistency

Temperature consistency is crucial for effective heat transfers. A machine with stable heat ensures designs adhere properly without issues like uneven transfers or damage. Look for models with digital temperature controls and displays for precise adjustments.

2. Pressure Adjustment

Different materials and thicknesses require specific pressure settings for optimal results. Choose a heat press with adjustable pressure controls, making it easy to customize for various substrates. Adjustable mechanisms ensure effective transfers and minimize errors.

3. Timer and Digital Controls

A built-in timer prevents overexposure to heat, avoiding scorching or damage to materials. Machines like the Cricut heat press offer user-friendly digital controls that ensure precise settings for time and temperature, making it easy to manage multiple projects efficiently.

4. Platen Size and Customization

The platen size determines the types of items you can press. Standard options range from 9″x12″ to larger sizes. For versatility, consider machines with interchangeable platens or larger surfaces if you plan to work on bigger projects or multiple items at once.

5. Manufacturer Reputation

Choose a heat press from a reputable manufacturer known for durability, quality, and customer service. Read user reviews and testimonials to assess the reliability of the model and brand.

6. Warranty and Service Options

A solid warranty protects your investment and ensures peace of mind. Look for machines with comprehensive warranties covering parts and labor, and check the availability of customer service for troubleshooting and repairs.

7. Loading and Accessibility

Ease of loading garments is vital for efficient workflows, especially during high-volume projects. A comprehensive heat press guide can help you choose designs like swing-away or draw presses that improve accessibility, reduce burn risks, and enhance productivity.

8. Budget Considerations

Heat presses vary in price, so set a budget that balances quality and cost. Investing in a high-quality machine may seem expensive initially but saves money in the long run due to durability and better performance. Explore options within your range while prioritizing essential features.

Understanding Your Needs and Business Goals for Choosing the Right Heat Press

Selecting the heat press is a crucial decision that depends on aligning your machine with your specific needs and business goals. Here’s a detailed guide to help you evaluate your requirements effectively:

1. Define Your Business Purpose

Understanding the primary purpose of your heat press is essential. Consider these points:

- Product Focus: Will you be printing t-shirts, hats, bags, or other items? If your focus is on heat press for shirts, ensure the machine is designed to handle various shirt materials and sizes effectively.

- Production Scale: Are you targeting small-scale custom jobs or large-volume orders? High-volume operations often need more robust and efficient machines.

2. Assess Your Target Market

Identifying your target audience can guide your equipment choices:

- Customer Base: Are you catering to individuals, businesses, or events? Knowing your customers helps you decide on the necessary features and capabilities.

- Market Trends: Stay informed about customization trends to choose products that will be in demand.

3. Evaluate Production Volume

Your expected production volume influences your machine choice:

- Frequency of Use: For daily use, invest in a professional-grade heat press for durability.

- Capacity Needs: High-volume operations may benefit from automatic machines that handle workloads efficiently.

4. Consider Space Limitations

Your workspace availability is a key factor:

- Machine Size: Ensure the heat press fits your space comfortably. Compact models are ideal for smaller areas.

- Accessibility: Look for designs that allow easy loading and unloading of items, such as swing-away or draw-style machines.

5. Identify Required Features

Heat presses come with various features to suit different needs:

- Temperature Control: Precise temperature settings ensure consistent, high-quality results.

- Pressure Adjustment: Adjustable pressure settings accommodate different materials and thicknesses.

- Platen Size: Choose a platen size that fits the items you’ll press. Larger platens are necessary for big designs.

6. Budget Considerations

Establishing a budget helps narrow down your options:

- Price Range: Heat presses vary in cost; balance affordability with quality and long-term value.

- Cost vs. Features: Investing in a higher-quality machine may save money in the long run through better durability and performance.

7. Research Brand Reputation

The manufacturer’s reputation significantly impacts your purchase decision:

- Quality and Reliability: Opt for well-known brands offering durable machines and excellent customer support.

- Warranty Options: A comprehensive warranty ensures peace of mind and protection against defects or malfunctions.

8. Plan for Future Growth

Think about your business’s potential evolution:

- Expandability: Choose a heat press that supports upgrades or additional attachments to accommodate future needs.

- Versatility: A machine capable of handling various materials ensures adaptability as your business grows.

Top Brands and Models of Heat Press Machines

Choosing a reputable brand and model is essential to ensure reliability and efficiency in your heat transfer projects. Here’s a list of some popular right heat press machines tailored for various needs:

- HTVRONT Auto Heat Press: Best overall heat press machine with an automatic pressing mechanism and dual-zone heating.

- Fancierstudio DG Heat Press: Best professional heat press with a large 16×24 inch platen and temperature range up to 500°F.

- Cricut EasyPress 3: Best for home use; a smart heat press known for its portability and user-friendly design.

- F2C Pro Heat Press Machine: Best multipurpose heat press with multiple functions and a platen size of 12×15 inches.

- Cricut Mug Press: Best for cylindrical projects, specifically designed for sublimation mugs.

- HYTIREBY Heat Press Machine: Best budget-friendly option, suitable for small designs and basic heat transfer tasks.

- Siser Craft Heat Press: A reliable traditional HTV machine offering digital controls and professional results.

- PowerPress Industrial-Quality Heat Press Machine: Ideal for larger projects with a lever design for easy operation and an LCD control board.

- Aonsey Heat Press: A cost-effective alternative with reliable results and an LED display.

- UKCutter Heat Press Machine (8-in-1): Offers versatility with multiple attachments for various heat transfer applications.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Wrap Up: Choosing the Right Heat Press Machine

Choosing the best heat press for your needs requires careful consideration of various factors. By prioritizing quality, efficiency, and support over initial cost, you can make an informed decision that will serve you well in the long run.

Remember to always follow the manufacturer’s instructions, maintain your heat press regularly, and prioritize safety when operating the machine.

If you need high-quality vectorization service, feel free to contact us. We offer affordable vector art services with a promise of high quality. If you are ordering from us for the first time, you’ll get 50% off, so grab this offer before it ends! If you enjoyed this article, please share it with your friends and family.

If you have experience with screen printing, feel free to mention it in the comment section. Embrace the journey, engage with your audience, and watch your brand flourish!

FAQs

A heat press is a machine designed to imprint a design or graphic on a substrate, such as a T-shirt, with the application of heat and pressure for a set period of time. It’s commonly used in the garment industry to create custom apparel.

A heat press works by using high temperatures and heavy pressure to transfer a design from a transfer paper or vinyl onto a fabric or other materials. The process involves placing the design on the substrate, setting the correct temperature, pressure, and time, and then pressing the machine down to apply heat and pressure.

A heat press can be used for various applications, including creating custom T-shirts, printing designs on hats, bags, and other clothing items, and making personalized gifts. It can also be used for pressing rhinestones and applying heat transfer vinyl.

There are several types of heat presses available, including:

- Clamshell Heat Press: Opens like a clamshell and is compact, making it ideal for small spaces.

- Swing-Away Heat Press: The upper platen swings away, providing more workspace and reducing the risk of accidental burns.

- Draw Heat Press: The lower platen pulls out like a drawer, allowing easier placement of items.

- Multifunction Heat Press: Comes with attachments for various substrates, such as mugs, hats, and plates.

When buying a heat press, consider the following factors:

- Size: Choose a size that fits the items you plan to press and the space available.

- Temperature and Pressure Control: Look for precise controls to ensure consistent results.

- Durability and Build Quality: A well-built machine will last longer and provide better performance.

- Type of Heat Press: Consider the type that best suits your needs, whether it’s clamshell, swing-away, or multifunction.

- Budget: Determine your budget and find a machine that offers the best features within that range.