Choosing between DTG vs screen printing for your next project? It’s a common question many people face when deciding how to best produce their custom designs. Each printing method offers distinct benefits, depending on what you’re looking to achieve. In this article, we’ll dive deep into the differences between DTG (direct-to-garment) and screen silk printing, helping you understand which technique might be the better choice for your specific needs.Let’s break it down and see which method comes out on top!

Which Is better DTG Vs Screen Printing

What is DTG Printing?

DTG, or Direct to Garment printing, is a way to print designs directly onto clothes like t-shirts. It uses a special printer that works kind of like the one you might have at home, but it prints on fabric instead of paper.

You can print detailed designs and even photos with lots of colors. It’s great for making just a few shirts at a time because it doesn’t need a lot of setup.

Key Features

- High Detail Accuracy: DTG can print very detailed images, making it perfect for designs with lots of colors and intricate patterns.

- Color Variety: This method can use many colors without any extra setup, which is different from other printing methods that might need more work for more colors.

- Quick Setup: There’s hardly any setup needed, so it’s faster to start printing, especially for small orders.

Benefits and Limitations

Benefits |

|

Limitations |

|

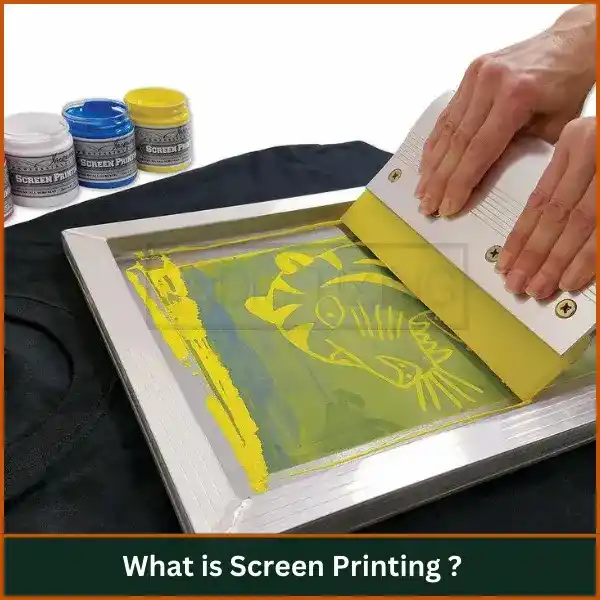

What is Screen Printing?

It is a popular method for creating designs on various materials, especially fabric. It involves pushing ink through a mesh screen that has been prepared with a stencil of the design.

This technique is widely used for making large batches of t-shirts, posters, and other items because it’s efficient for mass production. Each color in the design requires a different screen, making the setup more complex but highly effective for large orders.

Key Features

- Layering of Colors: It allows for vibrant colors to be layered on top of each other, producing rich and bright outcomes.

- Versatility: It can be used on a wide range of materials including textiles, metals, wood, paper, and glass.

- Durability: The prints are very durable and hold up well to washing and heavy use.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Benefits and Limitations

Benefits |

|

Limitations |

|

Difference Between DTG vs Screen Printing

Let’s explore the key differences to help you choose the best method for your project!

- Printing Process

- Color Capability

- Cost Efficiency

- Setup Time

- Print Durability

- Material Suitability

- Production Speed

- Detail and Resolution

- Order Volume Suitability

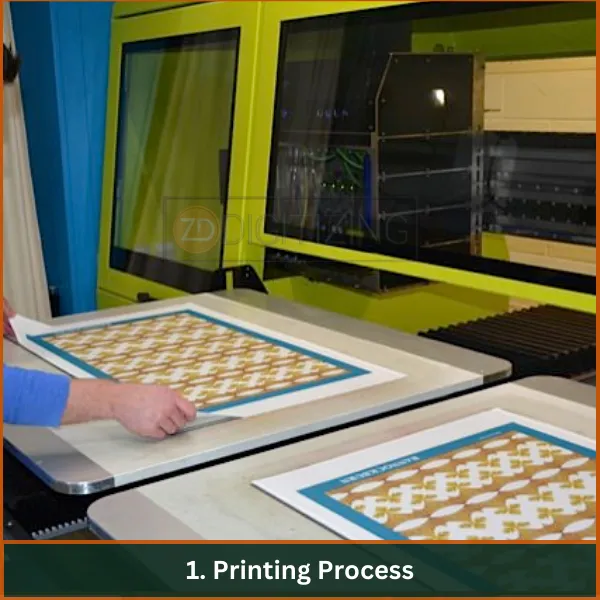

1. Printing Process

The DTG printing vs screen printing process highlights distinct approaches. DTG (direct-to-garment) employs inkjet technology to spray ink directly onto garments, allowing for precise and detailed imagery with minimal setup.

In contrast, screen silk printing involves pressing ink through stenciled screens, making it ideal for larger batches but requiring extensive setup for multi-color designs.

2. Color Capability

When comparing DTG and screen printing quality, DTG stands out for its ability to handle complex color gradients and intricate multi-colored designs without additional setup, perfect for detailed artistic patterns.

Printing on screen, however, is better suited for vibrant and consistent color applications, especially on a large scale, but each color increases setup requirements.

3. Cost Efficiency

Screen printing vs DTG in terms of cost efficiency reveals that screen silk printing is more economical for large volumes due to the reduced cost per unit after initial setup.

DTG, while lower in setup costs, tends to be pricier for larger batches due to the cost of inks and the slower printing process.

4. Setup Time

DTG boasts a quick setup time, making it excellent for small orders and designs that require high detail with multiple colors.

It counterpart requires more time for setup as each color needs a separate screen, making it less efficient for quick turnaround times but excellent for high-volume orders once setup is completed.

5. Print Durability

DTG vs screen printing durability is an important consideration. Printing on screen generally offers greater durability, suitable for garments needing to withstand extensive wear and washing.

DTG prints, while vibrant and detailed, may fade faster, especially if the ink isn’t properly cured.

6. Material Suitability

DTG is particularly effective on cotton fabrics where ink absorption is optimal. However, its performance on synthetic fabrics like polyester can be inconsistent.

Screen printing offers broader material versatility, capable of printing on a variety of substrates including challenging materials like synthetics and leather.

7. Production Speed

In the context of DTG printing vs screen printing, printing on screen leads in speed for producing large orders once the setup is complete, capable of printing thousands of shirts in a single day. DTG, while excellent for smaller orders, involves a slower process that does not scale as efficiently for large batches.

8. Detail and Resolution

DTG is superior for projects requiring high resolution and intricate details, as it can precisely replicate complex images and subtle color transitions.

Screen printing, while effective for bold and graphic designs, may not capture the same level of detail due to limitations in screen mesh fidelity.

9. Order Volume Suitability

For small to medium volumes and projects requiring detailed, customized designs, DTG is more suitable due to its flexibility and minimal setup. Its counterpart becomes more practical and cost-effective for very large orders, where its setup time and cost per unit become advantages.

Quick Difference Between Screen Printing vs DTG Printing

Feature | Screen Printing | DTG Printing |

Process | Uses stencils and screens. | Inkjet technology direct to fabric. |

Colors | Vibrant, solid colors; multiple screens needed. | Complex colors and gradients easily handled. |

Cost | Economical for large volumes. | Cost-effective for small runs. |

Setup | Time-intensive setup for colors. | Quick and minimal setup. |

Durability | Highly durable prints. | Prints may fade with washing. |

Materials | Versatile across many substrates. | Best on 100% cotton. |

Speed | Fast for large orders post-setup. | Slower, suited for low volumes. |

Detail | Limited by screen mesh. | High detail and resolution. |

Volume Suitability | Ideal for bulk orders. | Preferable for limited quantities. |

Best Situations to Choose Screen Printing

- Large Volume Orders: It is most cost-effective for large batches of prints, making it ideal for large-scale orders where cost per unit needs to be minimized.

- Simple Color Designs: For designs that use few colors, this is a robust choice because it produces vibrant and saturated colors very effectively.

- Durable Needs: Products that require a high degree of durability and resistance to wear and washing, such as work uniforms or outdoor clothing, benefit from the robust nature of screen-printed designs.

- Variety of Materials: If you need to print on a variety of materials, including challenging substrates like vinyl, metal, or plastic, it is the superior method due to its versatility.

- Budget Constraints: For those working within a strict budget, this printing method can offer more bang for the buck with larger orders.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Best Situations to Choose DTG Printing

- Small to Medium Orders: DTG is perfect for small to medium quantities due to its minimal setup, making it ideal for boutique fashion lines or customized merchandise.

- Complex Images: If the design includes high-resolution images or a wide range of colors, DTG is preferable for its ability to handle detailed graphics and photorealistic prints.

- Rapid Turnaround: When quick production and fulfillment are required, DTG can offer faster turnaround times because it skips the extensive setup of this method.

- Eco-Friendly Concerns: DTG uses water-based inks and has a more contained printing process with less waste, making it a greener choice compared to traditional screen silk printing methods.

- Cotton Materials: Since DTG printing excels on 100% cotton items, it’s a great option for high-quality cotton apparel that showcases intricate designs with shading and color gradients.

Conclusion: Choosing Between DTG vs Screen Printing

In the end, both DTG and screen printing have their strengths, depending on your project. Whether you need detailed prints or large orders, the right choice will depend on your needs.

For those looking for precision and customization, our vector art services at ZDigitizing enhance your printing projects. We provide high-quality designs with fast turnaround times and affordable pricing, ensuring your projects shine regardless of the chosen printing method.

Plus, new customers get 50% off their first order! Contact us now and let us help make your next project a success!

FAQs

DTG printing may not last as long as screen silk printing, as the latter often provides more durable and vibrant results over time.

DTG printing is generally more expensive than screen silk printing, especially for large quantities, due to higher equipment and material costs.

DTG works well on 100% cotton and other natural fibers, producing high-quality prints on these materials.

While DTG prints can fade over time with regular washing, proper care can help prolong the lifespan of the prints.