Are you curious about the differences between weaving and machine embroidery? These two techniques are staples in the textile world, but they serve very different purposes. Weaving involves intertwining threads to create fabric, a foundational method used for centuries. On the other hand, machine embroidery is all about embellishing fabric with decorative stitches, adding unique patterns and designs.

Both processes are fascinating in their own right and play crucial roles in fashion and fabric manufacturing. Let’s dive deeper to understand how they differ and where each excels.

Difference Between Weaving and Machine Embroidery

What is Weaving?

It is a textile production method that involves interlacing two sets of threads or yarns at right angles to form a fabric or cloth.

The threads running lengthwise are called the warp, and the threads running across from side to side are called the weft. This method is used to create various types of fabrics, from delicate silks to sturdy denims.

Types of Weaving Techniques

- Plain Weave: The most basic and common weaving technique where the weft thread crosses the warp thread by going over one and under the next, alternating each row.

- Twill Weave: Recognizable by its diagonal rib pattern, this technique involves the weft crossing over two or more warp threads before going under one or more, which gives it a distinct diagonal pattern.

- Satin Weave: Known for its smooth, shiny surface, the satin weave allows threads to float over others at large intervals before being tucked under, creating a high sheen.

- Jacquard Weave: This technique allows for complex patterns to be created directly in the fabric through a mechanism that controls each warp thread independently.

- Dobby Weave: Similar to Jacquard but less complex, dobby weaves use a dobby mechanism to weave more intricate patterns than plain weaves but are limited to simple geometric figures.

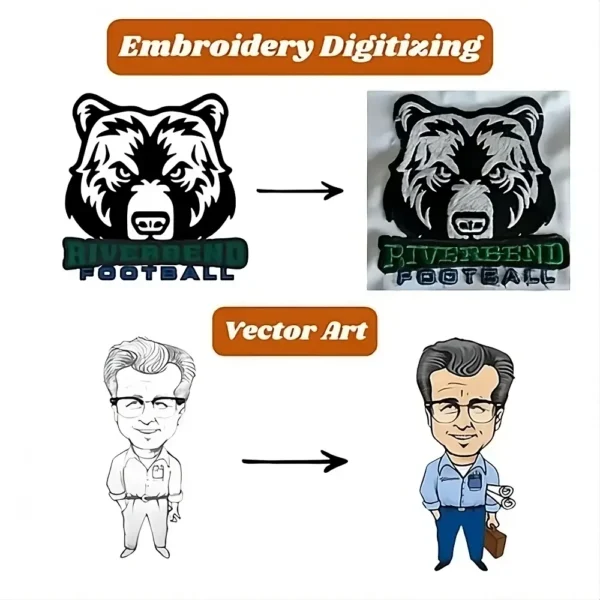

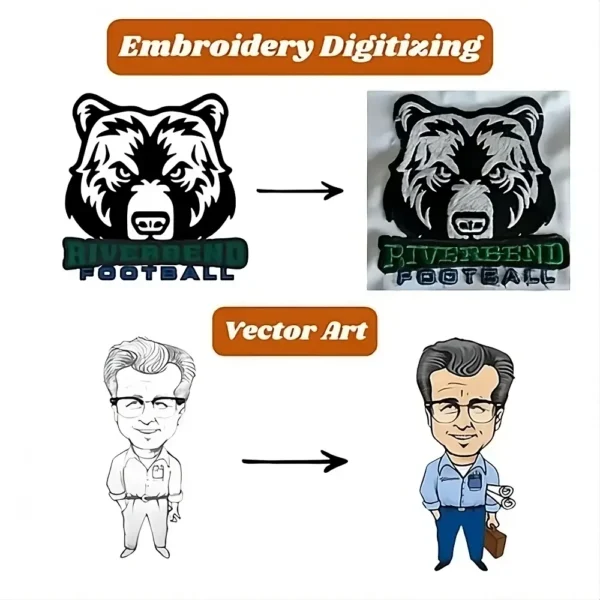

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Pros and Cons of Weaving

Pros |

|

Cons |

|

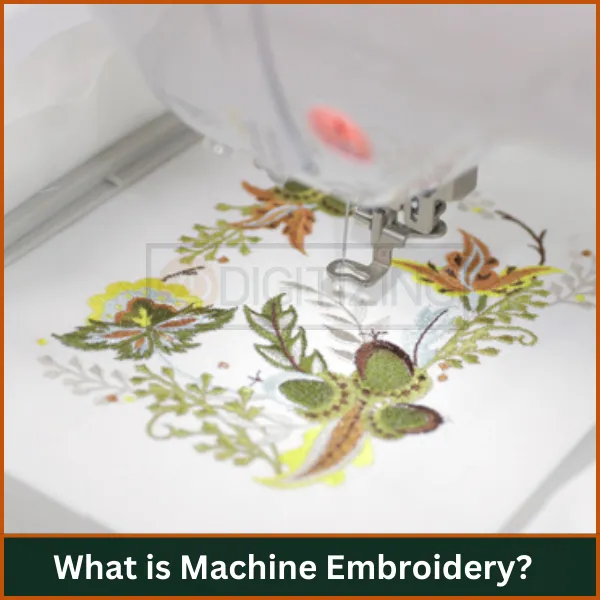

What is Machine Embroidery?

It is a process that uses a sewing machine or embroidery machine to create patterns on textiles. It is used for decorating fabric and branding articles like logos on uniforms and merchandise.

The designs are digitized with embroidery software and then loaded into the machine, which stitches out the pattern using one or more colored threads automatically.

Types of Machine Embroidery Techniques

- Free-Motion Embroidery: This technique involves moving the fabric freely under the needle, controlled by the embroiderer, allowing for artistic and freeform designs.

- Appliqué Embroidery: Involves sewing a piece of fabric onto a larger one to create designs, often with a satin stitch border.

- 3D Puff Embroidery: A technique that uses foam under the stitching to give the embroidery a three-dimensional look, ideal for caps and hats.

- In-the-Hoop Embroidery: Entire projects are completed within the embroidery hoop, including sewing and finishing touches, perfect for quilt blocks and stuffed items.

- Patch Embroidery: Specifically aimed at creating patches, this technique often involves heavy-duty materials and adhesive backings.

Pros and Cons of Machine Embroidery

Pros |

|

Cons |

|

Key Differences Between Weaving and Machine Embroidery

Weaving and Embroidery serve different functions within the textile industry, each with unique processes and outcomes. The differences are:

- Purpose and Use

- Fabric Creation vs. Fabric Decoration

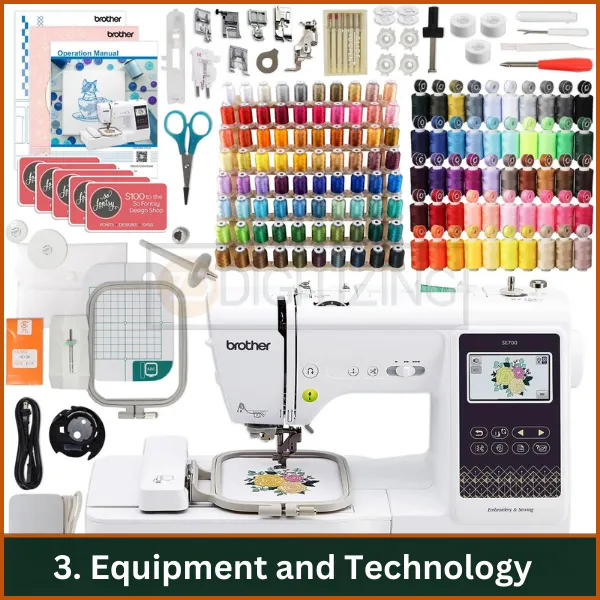

- Equipment and Technology

- Material and Thread Handling

- Skill and Labor Requirements

- Production Speed and Efficiency

- Flexibility and Customization

- Cost of Setup and Operation

1. Purpose and Use

Weaving creates the fabric itself, forming the basic structure of textiles from scratch through the interlacing of yarns or threads. In contrast, machine embroidery is primarily used for decorating pre-existing fabrics with threads to add patterns, logos, or artwork.

2. Fabric Creation vs. Fabric Decoration

Weaving and Machine Embroidery differ significantly in their end products; weaving is about constructing textiles, fundamental for producing a wide range of fabric-based products. Machine embroidery focuses on enhancing or beautifying fabric surfaces with decorative stitching, making it integral to industries that value aesthetics, such as fashion and home decor.

3. Equipment and Technology

Weaving utilizes looms that can range from simple hand-operated frames to complex automated machines that produce vast quantities of fabric. Machine embroidery employs specialized machines that can render intricate designs digitally onto fabric.

4. Material and Thread Handling

In weaving, both the warp and the weft threads are essential for fabric creation. Embroidery, particularly techniques like bead embroidery and bead weaving, involves not only threads but also the incorporation of other materials like beads, enhancing the textile’s visual appeal and texture.

5. Skill and Labor Requirements

Both weaving and machine Embroidery require skillful execution, but weaving can be more labor-intensive, especially in its more traditional forms. Embroidery might require technical skill in design digitization and machine operation, reflecting a blend of artistic and technical expertise.

6. Production Speed and Efficiency

Generally, modern weaving processes are faster due to mechanization and are efficient for large-scale fabric production. Machine embroidery, while automated, can be slower depending on the complexity and size of the decorative designs.

7. Flexibility and Customization

Machine embroidery offers greater flexibility in customization, allowing for intricate and varied artistic designs that can be easily altered and reproduced. Weaving offers less flexibility once the loom is set up but can produce more structurally diverse fabrics.

8. Cost of Setup and Operation

The cost of setting up looms for weaving Vs embroidery can be high, especially for large-scale operations. Embroidery machines also represent a significant investment but are typically less costly in terms of both setup and materials unless high-end, multifunctional machines are used.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Choosing Between Weaving vs Machine Embroidery

When it comes to picking between these techniques, think about what you need for your project. Weaving is great if you’re starting from scratch and need to make the fabric itself. It’s perfect for creating everything from sturdy towels to soft shirts.

On the other hand, machine embroidery is the way to go if you want to add some special touches to already-made fabrics. It lets you stitch in beautiful patterns or logos, which is ideal for personalizing items or making your business stand out.

So, think about your project’s goal: Do you need to make the base fabric, or do you want to decorate and personalize what you already have?

Your answer will guide you to the right choice, whether it’s weaving or embroidery.

Conclusion

So, now you know the difference between weaving and machine embroidery: one builds the fabric, and the other adds flair to it.

If you’re interested in adding unique embroidery designs to your projects, our digitizing services can help make that happen. We turn any design into an embroidery file quickly and affordably, ensuring top-notch quality every time.

Plus, if you’re new to our services, you’ll get a 50% discount on your first order. So, order now!

FAQs

Stitching involves joining fabric pieces together or creating designs on fabric using needle and thread, while weaving is the process of interlacing two sets of threads at right angles to form a fabric.

The two types of machine embroidery are free-motion machine embroidery, which allows for manual control of the stitching with a basic sewing machine, and computerized machine embroidery, where designs are digitized and stitched automatically by the machine.

Weaving is the craft of creating fabric by interlocking two distinct sets of yarns or threads, known as the warp and the weft, on a loom.

Machine embroidery is a technique where a sewing or embroidery machine is used to create patterns on textiles, utilizing pre-programmed designs or patterns that are inputted into the machine.