Wondering what the future of screen printing looks like? This industry is changing quickly, thanks to new technology and creative methods. As screen printing continues to grow, it’s becoming faster, more efficient, and even more exciting. From cutting-edge screens that offer better detail to automation that saves time and effort, the future is full of improvements.

Whether you’re a business owner or just love the art of printing, keeping up with these changes can help you get the most out of this evolving craft. Let’s dive into the trends shaping what’s next for screen printing!

What is the Future of Screen Printing

Future of Screen Printing: Emerging Trends and Innovations

It is being shaped by remarkable advancements in technology, offering increased efficiency, creativity, and sustainability across the industry.

- High-Resolution Screens

- Inline Pretreatment and Curing Stations

- Specialty Inks (Metallic, Glow-in-the-Dark, High Density, 3D Effects)

- Digital File Preparation

- Automated Screen Cleaning and Recycling Systems

- Computer-to-Screen Systems

- Hybrid Machines (Digital and Analog Technology)

- Touchscreen Automatic Screen Printing Presses

- Self-Diagnostics and Wi-Fi Compatible Systems

- Roller Squeegees

- Artificial Intelligence in Design and Workflow

- Direct-to-Mesh (DTM) Technology

- Automation in Post-Press Activities

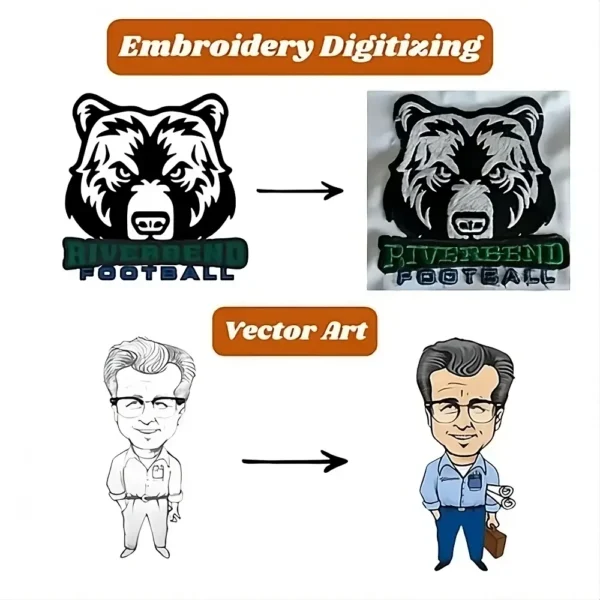

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

1. High-Resolution Screens

High-resolution screens use finer mesh counts to print intricate designs with great detail and clarity. This allows brands to create visually impressive products that stand out. These screens also improve color accuracy, ensuring the printed design looks very close to the original.

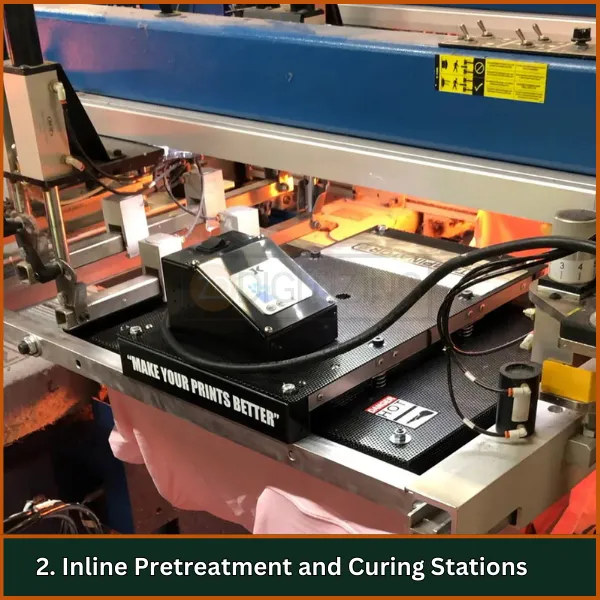

2. Inline Pretreatment and Curing Stations

Inline pretreatment and curing stations prepare materials, like fabric or paper, before printing and cure them immediately after. This process saves time, reduces labor costs, and makes the prints last longer. By combining these steps, the future of screen printing becomes more efficient and ensures consistent quality.

3. Specialty Inks

Specialty inks, such as metallic, glow-in-the-dark, and high-density inks, bring new creative possibilities to screen printing. These inks add unique finishes and effects, allowing brands to stand out in niche markets and offer exciting new products.

4. Digital File Preparation

Digital file preparation tools make it easier to optimize designs for screen printing. These tools automatically adjust artwork to meet printing requirements, reducing mistakes and speeding up the production process. This technology ensures that designs are ready for printing, cutting waste, and boosting productivity.

5. Automated Screen Cleaning and Recycling Systems

Automated screen cleaning systems remove ink residues and reclaim emulsion from screens, allowing printers to reuse them effectively. These systems reduce downtime and waste, promoting a more eco-friendly printing process. They are a key part of the future of screen printing industry, improving sustainability and reducing labor.

6. Computer-to-Screen Systems

Computer-to-screen (CTS) technology directly transfers digital images onto screens, eliminating the need for film positives. This technology speeds up setup, improves accuracy, and reduces material costs. It also makes design changes easier, allowing faster turnaround for custom orders.

7. Hybrid Machines

Hybrid machines combine digital printing with traditional screen printing, offering more flexible production options. These machines handle large print runs and can still manage custom designs. By blending both methods, hybrid machines meet customer demands without sacrificing speed or quality.

8. Touchscreen Automatic Screen Printing Presses

Touchscreen automatic screen printing presses come with easy-to-use interfaces. These intuitive controls help operators adjust settings like speed, pressure, and alignment quickly, even without much training. This boosts productivity and shortens setup times, making production faster and more efficient.

9. Self-Diagnostics and Wi-Fi Compatible Systems

Modern printing presses use smart technology that includes self-diagnostics and Wi-Fi compatibility. These systems monitor performance in real-time, detecting issues before they cause serious problems. Operators can check performance data remotely, allowing for proactive maintenance and reducing production downtime.

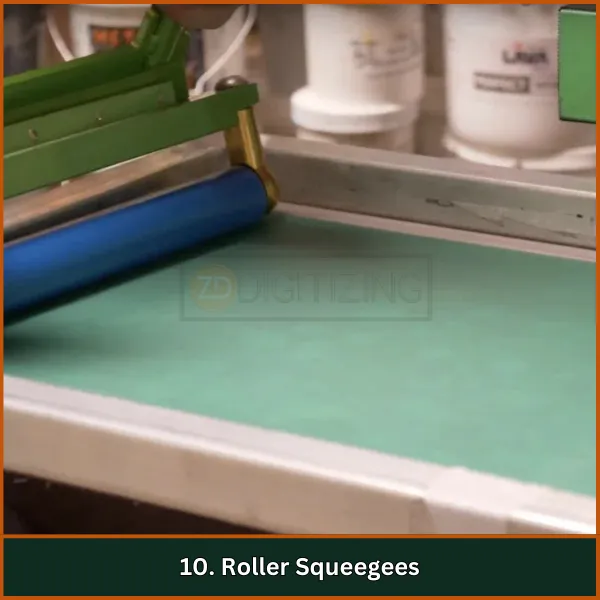

10. Roller Squeegees

Roller squeegees improve the efficiency of ink transfer by applying even pressure across the material. This ensures consistent ink distribution, which improves the quality of printed designs and reduces waste. This is a key improvement in the future of screen printing technology, ensuring better print quality and less material waste.

11. Artificial Intelligence in Design and Workflow

Artificial intelligence (AI) is helping screen printing by optimizing design layouts, predicting when maintenance is needed, and making production workflows more efficient. AI tools analyze data to spot patterns that can save time and reduce costs, ultimately speeding up production and delivering better results for clients.

12. Direct-to-Mesh Technology

Direct-to-mesh (DTM) technology allows printers to print directly onto mesh screens instead of using film positives. This speeds up the setup process by eliminating extra steps and ensuring precise placement of images, saving both time and material costs.

13. Automation in Post-Press Activities

Automation extends beyond printing to post-press activities like cutting, folding, or packaging. Automated solutions reduce the need for manual labor, increase production speed, and ensure products are delivered on time without compromising on quality.

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Final Words

In simple words, future of screen printing is getting better and faster, with new ideas that will make printing more fun and creative. By knowing what’s coming, you can do your screen printing projects even better.

If you need help with designs for your screen printing, ZDigitizing is here for you. We offer quick service, affordable prices, and high-quality designs to make sure your prints look amazing. Try us today and get 50% off your first order!

FAQs

The screen printing industry is experiencing growth, driven by demand in textiles, packaging, and custom merchandise sectors.

Screen printing offers diverse possibilities, including high-quality prints on various materials, durability, and cost-effectiveness for large runs.

Screen printing is not outdated; it remains popular for its versatility, quality, and economic benefits in bulk production.

Digital printing is often considered better than screen printing for short runs due to its precision, ability to print complex designs and faster turnaround time.