Investing in an automatic screen printing press can be a game-changer for print shops ready to scale up from manual operations. Whether you’re a small business owner or a growing custom apparel brand, understanding what to expect before making this big purchase is crucial. This article covers the essentials, from space requirements and production capacity to hidden costs and learning curves, so you can make a smart, informed decision.

We’ll also highlight common mistakes beginners make and how to avoid them. Thinking about automating your shop but unsure if it’s the right move? Let’s explore what you really need to know.

Beginner’s Guide on Automatic Screen Printing Press | What You Need to Know

What Is an Automatic Screen Printing Press?

It is a machine that automates the screen printing process, using motors and pneumatics to handle the movements of the screens, squeegees, and platens. Unlike manual presses, which require physical effort for each step, automatic presses can print hundreds of garments per hour with minimal operator input.

An automatic screen printing press machine is ideal for shops handling high-volume orders or looking to improve consistency and efficiency. It’s often the next step for businesses ready to scale beyond manual setups.

Pros & Cons of an Automatic Printing Press

Pros | Cons |

|

|

Understanding how an automatic press works is the first step in deciding if it’s the right fit for your growing business.

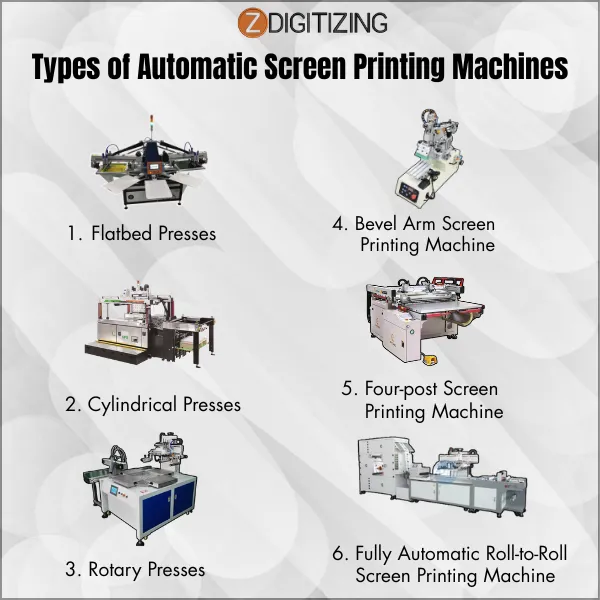

Types of Automatic Screen Printing Machines

There are many types of screen printing automatic press, each built for different materials, shapes, and production needs. Choosing the right type depends on what you’re printing, flat items, garments, bottles, or rolls of fabric.

- Flatbed Presses

- Cylindrical Presses

- Rotary Presses

- Bevel Arm Screen Printing Machine

- Four-post Screen Printing Machine

- Fully Automatic Roll-to-Roll Screen Printing Machine

1. Flatbed Presses

Flatbed screen printing presses are designed for printing on flat, rigid surfaces. They’re commonly used to print on items like glass panels, wooden boards, plastic sheets, signs, and electronic components. These machines work by placing the object on a flat surface, then the screen lowers vertically to apply ink. They offer excellent accuracy and are known for delivering crisp prints on non-porous or hard materials.

Price Range: $15,000 – $60,000

Ideal For: Industrial product branding, signage businesses, glass or electronics printing.

2. Cylindrical Presses

They are used to print on round or curved surfaces. The item rotates while the screen and squeegee apply ink evenly around the object. This type of machine is popular for printing on drinkware like bottles, mugs, jars, or cosmetic tubes. It ensures consistent results and high efficiency when handling curved shapes.

Price Range: $8,000 – $40,000

Ideal For: Packaging companies, promotional product printing, cosmetics manufacturers.

3. Rotary Presses

They use circular, rotating platens that allow multiple prints to be completed simultaneously. This setup reduces idle time and increases printing speed, making them ideal for handling large-volume textile printing jobs. These presses are often used by manufacturers with heavy order loads and strict delivery timelines.

Price Range: $30,000 – $120,000+

Ideal For: High-volume garment production facilities and print-on-demand services.

4. Bevel Arm Screen Printing Machine

Bevel arm screen printing machines feature a unique angled arm, allowing easier access to thick or elevated surfaces. These machines are especially useful when printing on items that are not perfectly flat or lie above the printing surface like boxes, cases, or irregular promotional products.

Price Range: $4,000 – $18,000

Ideal For: Specialty printing on packaging, custom boxes, and uneven surfaces.

5. Four post Screen Printing Machine

This type of machine is supported by four sturdy posts that provide excellent balance and pressure distribution. The design helps ensure uniform ink application across large or heavy materials. It’s ideal for precise, technical printing jobs where movement or tilt could ruin the print.

Price Range: $10,000 – $40,000

Ideal For: Industrial parts printing, heavy panels, and detailed graphic work.

6. Fully Automatic Roll to Roll Screen Printing Machine

Roll-to-roll press are built for nonstop production on roll materials like fabric, film, or vinyl. These high-end machines automate everything from feeding the material to printing and drying, making them efficient for mass production environments. They’re widely used in industries that require fast, repeatable patterns over large lengths.

Price Range: $100,000 – $300,000+

Ideal For: Industrial fabric printing, wallpaper production, and continuous roll-label applications.

Key Features to Consider Before Buying Automatic Screen Printing Press

Before you invest in an automatic printing machine, it’s essential to understand the features that directly impact your production, workflow, and long-term business growth. Choosing the right machine isn’t just about speed it’s about compatibility with your space, budget, and goals.

Here are the key features to consider:

- Machine Configuration (Number of Colors and Stations)

- Space and Shop Layout

- Power and Electrical Requirements

- Budget and Return on Investment (ROI)

- Type: All-Electric vs. Pneumatic

- Printing Quality and Precision

- Control System (Computerized vs. Manual)

- Essential Features (Screen Clamps, Off-Contact Control, Squeegee Setup, Safety Features)

- Maintenance and Support Availability

- Production Volume and Scalability

1. Machine Configuration (Number of Colors and Stations)

The number of print heads (colors) and stations (platens) directly affects your production capacity and design capabilities. A 6-color/8-station configuration is ideal for standard multi-color designs, offering space for loading, printing, flashing, and unloading garments efficiently.

Larger setups, like 10-color/12-station presses, are perfect for complex jobs and faster output. This is the foundation of any screen printing press buying guide start with your design needs and match them to the right configuration.

More stations reduce bottlenecks, while more colors expand your design offerings.

2. Space and Shop Layout

Automatic presses are large and require generous space for operation and maintenance. Before purchasing, assess your available floor area, considering the diameter of the machine, room for operators, screens, ink stations, and drying units.

Crowded setups can limit efficiency and create safety hazards. Proper layout planning also improves material flow and reduces production delays. Even the best automatic screen printing press will underperform if installed in a cramped or disorganized environment.

If your shop has limited space, a small automatic screen printing press can be a better choice, offering professional results without needing a large setup area.

3. Power and Electrical Requirements

Different presses have varying power needs. Most machines require 220V or 3-phase electricity, and pneumatic models need a reliable air compressor. Air-powered presses typically consume more energy and produce more noise, while all-electric models operate more quietly and use standard power connections.

If your facility isn’t already equipped for higher voltage or air supply, additional upgrades may be necessary before installation.

Make sure your chosen screen printing automatic press is compatible with your shop’s power setup to avoid delays or added costs.

4. Budget and Return on Investment (ROI)

Pricing can vary widely, from entry-level models starting at $20,000 to industrial-grade presses costing over $100,000. When calculating the total automatic screen printing press price, include installation, training, accessories, maintenance tools, and shipping.

To determine your ROI, consider how many shirts per month you’ll need to print to cover the machine’s cost and start generating profit. The right investment balances affordability with long-term revenue growth. Don’t just go for the cheapest option look at reliability, lifespan, and feature set.

5. Type: All-Electric vs. Pneumatic

All-electric presses use motors instead of compressed air, offering quieter operation, fewer mechanical components, and lower long-term maintenance. Pneumatic presses rely on air compressors, which can be noisy and require more frequent upkeep but are often more budget-friendly upfront.

For businesses focused on efficiency and lower energy costs, all-electric machines may be the better choice.

If you’re looking for an automatic screen printing machine for t shirt production with lower startup costs, pneumatic may fit, but be prepared for added compressor costs and noise management.

6. Printing Quality and Precision

High-quality output depends on features like micro-registration, stable platen movement, and even squeegee pressure. Machines with poor alignment or unstable frames can produce misprints, especially in multi-color jobs. Look for systems that allow fine-tuning during setup and production.

A good press should hold registration through long runs, produce even ink coverage, and support halftones prints and detailed graphics. This is particularly important for fashion and promotional products, where quality affects brand reputation and customer satisfaction.

7. Control System (Computerized vs. Manual)

Modern automatic presses come with digital control systems that offer touchscreen interfaces, preset storage, real-time adjustments, and production tracking. These systems reduce human error, speed up setup, and allow for quick repeat jobs.

Manual controls may save money initially, but they lack the efficiency and consistency of computerized systems. When evaluating your options, consider how much time your team will save with automation and how much that time is worth in labor costs. For high-efficiency workflows, digital controls are a must.

8. Essential Features (Screen Clamps, Off-Contact Control, Squeegee Setup, Safety Features)

Key mechanical features affect setup speed, print quality, and safety. Quick-release screen clamps save time during job changes, while off-contact control helps ensure even ink transfer.

Adjustable squeegee angles and pressure settings allow for better control on different fabric types. Built-in safety features like emergency stop buttons, motion guards, and warning systems protect both operators and equipment. If you plan to run multiple jobs a day, these features can significantly improve output and reduce operator fatigue.

9. Maintenance and Support Availability

Like any machine, automatic presses need regular maintenance to operate smoothly. Before purchasing, check the manufacturer’s support options, including technical service, spare parts availability, and training.

Delays in repairs can cause production downtime and lost revenue. Choose a machine from a company with strong customer support, good documentation, and nearby service networks. Consider this a long-term partnership, not just a purchase.

10. Production Volume and Scalability

Finally, your machine should match not just your current production volume but also your growth plans. If you’re producing small batches now but expect to scale in the next year, choose a press that allows expansion without full replacement.

Some machines offer modular upgrades or support add-ons that make scaling easier. A scalable screen printing automatic press allows you to grow steadily without losing momentum or having to reinvest too soon.

How to Avoid Expensive Mistakes with Your First Automatic Screen Printer?

When investing in an automatic screen printing press for the first time, beginners often overlook key details that can affect performance, cost, and results. Here are some common pitfalls and how to avoid them:

- Rushing to buy without proper research, leading to machines that don’t fit production needs or shop space.

- Choosing a press based solely on price, ignoring build quality, support, and long-term reliability.

- Underestimating the learning curve, assuming the press will “run itself” without proper training.

- Failing to plan for power, air, and space requirements before installation.

- Overlooking the need for regular maintenance, which can result in costly breakdowns.

- Ignoring safety features, putting operators at risk and increasing liability.

- Not considering the total cost of ownership, including accessories, upgrades, and repairs.

- Selecting the wrong configuration (colors/stations) for current and future job types.

- Expecting instant ROI without accounting for downtime, training, and process adjustments.

- Skipping proper onboarding and staff training, which can lead to errors, waste, and inconsistent results.

Maintenance and Cleaning of Automatic Presses

Proper maintenance and cleaning are key to keeping your automatic screen printing press running smoothly and extending its lifespan. Regular care helps prevent breakdowns, improves print quality, and reduces unexpected repair costs.

- Clean squeegees, flood bars, and platens after each shift to avoid ink buildup.

- Wipe down the press frame and print heads to prevent dust and lint accumulation.

- Check for loose bolts, worn belts, or air leaks weekly.

- Lubricate moving parts like arms and carousels as per the manufacturer’s guidelines.

- Inspect and replace damaged or clogged mesh screens promptly.

- Keep control panels and sensors free of ink and debris to avoid malfunctions.

- Perform scheduled software updates and calibration if the press is computerized.

- Drain and clean the air compressor regularly if using a pneumatic press.

- Maintain a logbook to track service intervals and issues for early troubleshooting.

Conclusion: Is an Automatic Screen Printing Press Right for You?

Choosing the right screen printing automatic press is a major step forward but it’s not a one-size-fits-all decision. Your shop’s space, budget, and business goals all play a role in determining whether it’s the right time to invest.

Before you make your final decision, ask yourself:

- Do I have enough space in my shop to install and operate the press safely?

- Can my current electrical and air supply support the machine’s requirements?

- Am I handling enough volume to justify the cost of automation?

- Do I have a clear plan for training myself or my team on the new press?

- Can I manage regular maintenance and unexpected repairs?

- Have I calculated the return on investment based on my current and future workload?

- Do I have the time and workflow setup to ensure smooth production once it arrives?

In addition to equipment, new print shops also need high-quality, vector-ready artwork for printing. Creating clean, production-ready designs can be a challenge for beginners and this is where many new businesses get stuck.

At ZDigitizing, we understand that starting or upgrading your print business is a big step and having the right designs is just as important as having the right machine.

That’s why we offer professional vector art and embroidery digitizing with super-fast turnaround, guaranteed quality, and 24/7 support. Enjoy 50% off your first order and special discounts on bulk.

Let us handle the design place your order today and get started with confidence!

FAQs

An automatic press is a machine that does the screen printing job by itself with little help from a person. It moves the screens, squeezes the ink, and turns the shirts automatically. This makes printing faster and more consistent compared to doing it by hand.

In automatic screen printing, the machine moves the printing platens, screens, and squeegees for you. You load the shirt, press start, and the machine prints each color, one by one, using perfect pressure and timing. It helps you print more shirts in less time with better quality.

A screen printing press holds the screens in place and helps push ink through the screen onto the shirt or fabric. It allows you to print designs on clothing like t-shirts, hoodies, or bags using special ink and screens with your design.

For most screen printing, the ink needs to be heated to 320°F (160°C) to fully cure. You can use a heat press and press the shirt for at least 40 seconds. If you don’t have a heat press, you can use a household iron carefully, but the results might not be as strong or long-lasting.

With an automatic screen printing press like the Trooper, you can print around 180 shirts per hour, even with detailed designs that use up to six colors. That’s much faster than manual printing, which usually prints around 50 to 60 shirts per hour.