If you’re getting into hat embroidery digitizing, you’re in the right place. Digitizing for hats isn’t like digitizing for flat items such as shirts, jackets, or bags. Hats are curved, structured, and limited in space, which means you need a different strategy to get clean and professional results. Many beginners think they can use the same techniques they’ve used for other embroidery projects, but that’s where mistakes begin.

Hat embroidery requires a deeper understanding of design placement, machine setup, fabric behavior, and file preparation.

Hat Embroidery Digitizing: 7 Things You Know Before Starting

Now, we’re about to cover exactly what you need to know before you begin. Here are the 7 most important things we’ll explore:

- Understanding Hat Curves and Design Placement

- Selecting the Right Embroidery Machine and Hoops

- Choosing Appropriate Stitch Density for Hats

- Digitizing for Hat Fabric and Material

- Managing Design Size and Resolution

- Test Stitching and Adjusting for Fit

- Saving and Exporting Embroidery Files Correctly

Let’s go through each of these points in detail, so you can avoid common mistakes and confidently digitize your next cap design the right way.

1. Understanding Hat Curves and Design Placement

Hats have different front structures, and that structure directly affects where and how you should place your design.

Design placement is especially tricky because the embroidery surface is small and not always symmetrical.

You also have to consider the center seam, the crown height, and how the hat bends when worn. This is why understanding hat types is essential before choosing a design or starting digitizing.

Let’s understand some of the most popular hat types today and how their shape impacts embroidery.

Hat Type | Front Curve | Design Placement Tip |

Structured Baseball Cap | Firm and curved | Keep the design slightly below the center seam |

Trucker Cap | Foam-front, slightly flat | Avoid stitching too close to the top corners |

5-Panel Hat | Flat front | Allows more accurate and detailed design placement |

Beanie | Stretchy and curved | Place design at mid or lower front for better visibility |

Unstructured Dad Hat | Soft front, collapses | Center your design lower than usual |

A common mistake beginners make is placing the design too high or too close to the seam. Since the seam and brim can distort stitches, always shift your design slightly downward and keep it centered.

2. Selecting the Right Embroidery Machine and Hoops

For hat embroidery digitizing, your machine matters a lot. Some embroidery machines are better equipped to handle curved surfaces than others. We recommend machines like the Brother PR1055X or Ricoma EM-1010, especially if you plan to do cap work regularly. Here’s why:

- Multi-needle capability for automatic color changes

- Supports specialized cap frames

- Adjustable tension settings (essential for thick caps)

- Screen preview for accurate placement

Now, let’s match hoops to the most used hat types:

Hat Type | Recommended Hoop | Why This Hoop Works |

Structured Baseball Cap | Curved wide cap frame | Matches the curve and gives tight grip |

Trucker Hat | Extra-wide curved cap frame | Holds the foam front well and prevents shifting |

Beanie | Small cylindrical or flat hoop | Maintains hold on stretch fabric |

5-Panel Hat | Flat cap frame | Flat surface makes this hoop perfect |

Using the wrong hoop can result in shifting fabric or poor alignment, which are common cap embroidery mistakes.

3. Choosing Appropriate Stitch Density for Hats

Now let’s talk about stitch density in general. Stitch density means how close the threads are placed together. It’s usually measured in millimeters (like 0.35mm between stitches). A smaller number means tighter stitches, while a larger number means looser ones.

Getting the density right is important because it affects how your design looks and how well it holds up on different hat materials. Too dense, and the fabric might pucker or the thread could break. Too loose, and the design may look incomplete or weak.

Rather than matching density to stitch type, it’s smarter to match it to your design size and hat material. Here’s a simple guide:

Design Size on Cap | Recommended Density (Satin/Fill) | Why This Works |

Small Text (4 mm – 6 mm) | 0.40 mm – 0.45 mm | Prevents stitches from overlapping too tightly |

Medium Elements (7 mm – 12 mm) | 0.35 mm – 0.40 mm | Balanced density for clean coverage |

Large Shapes (13 mm and above) | 0.30 mm – 0.35 mm | Tighter density for solid fill without gaps |

Background Fill or Knockdown | 0.50 mm – 0.60 mm | Lighter stitch for flattening surface underneath |

Tip: If your fabric is very thick (like foam or canvas), increase pull compensation slightly and always run a test on a spare cap before going into production.

4. Digitizing for Hat Fabric and Material

The material of the hat directly affects how you should digitize the design. Let’s walk through the most common materials and how to adjust your approach.

We’ll look at what’s used today, and how to handle it:

Cotton Twill Cap

This is the most common fabric for caps. It’s strong and stable, so it works well with medium-density fills and a firm underlay. Be sure to add some pull compensation to prevent small gaps.

Foam-Front Trucker Cap

The foam makes the surface soft and raised. For these, start your design from the center and use lower-density stitching with a knockdown stitch underneath to flatten the foam before stitching the main design.

Canvas or Denim Caps

These are thick and heavy fabrics. Use stronger needles and a higher-density stitch. Underlay should be strong to support the top stitching.

Mesh-Back Caps

Only digitize designs for the front panel. Avoid the mesh area as it won’t hold embroidery well. Stick with the same method as cotton twill for the front.

Beanies (Stretchy Knit)

Use ballpoint needles and low-density fill. Avoid tight stitching as it will pucker. An open fill pattern works best.

If you’re using embroidery digitizing software, make sure to choose the right fabric type before you start. This will adjust the stitch density and tension for you automatically.

5. Managing Design Size and Resolution

Every hat has limited space. If your design is too big or too detailed, it won’t stitch cleanly.

Here’s a simple guide to follow:

Hat Type | Max Height | Max Width | Best Design Tips |

Structured Baseball Cap | 2.25″–2.5″ | 4.5″–5″ | Use bold fonts and simple logos |

Trucker Cap | 2.5″–2.75″ | 5″ | Light details and open fill to reduce tension |

5-Panel Hat | Up to 2.75″ | Up to 5.5″ | Great for logos with detail and wide text |

Beanie | 1.5″–2″ | 3″–4″ | Small icons, initials, or simple text |

If your design isn’t already digitized, or if you don’t know how to create clean stitch paths, this is where you can trust ZDigitizing’s professional embroidery digitizing services. We ensure clean design conversion, smart stitch types, and perfectly optimized files for every cap type.

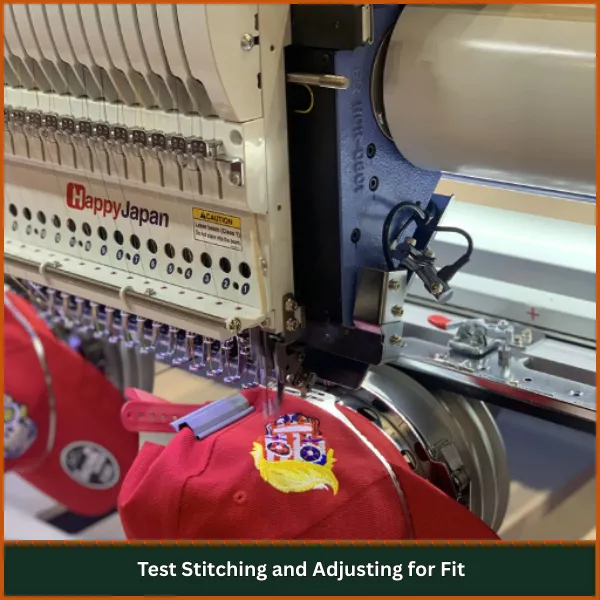

6. Test Stitching and Adjusting for Fit

Even if your design looks perfect on screen, always test it on an actual hat. Here’s what you should check:

- Is the design centered correctly?

- Are there any gaps or thread breaks?

- Does the design handle seams and curves well?

- Is the fabric pulling or wrinkling?

If anything looks off, go back to your digitizing file and make adjustments.

Sometimes just changing the underlay or increasing pull compensation is all it takes to fix the problem.

This step is crucial when you’re doing cap digitizing for custom orders or clients.

7. Saving and Exporting Embroidery Files Correctly

Once your hat design is digitized, save it in the correct format for your embroidery machine, like .DST, .PES, or .EXP. Using the wrong format can cause loading errors or misaligned stitching.

Before you export, make sure everything is in order: the stitch path should be optimized, color sequences should match your design plan, trim commands should be added between color blocks, and jump stitches should be clean. Also, double-check the starting and ending points of your design so that the machine moves smoothly from one element to another.

If you’re not confident in this final step or you’re unsure which file settings are best for your machine and fabric type, it’s okay to ask for help.

Conclusion

We’ve done our best to guide you through the key things you should know about hat embroidery digitizing, from understanding different hat styles and choosing suitable stitch types to selecting the right machine and exporting your design file correctly. We hope this information has helped you feel more confident and better prepared for your next cap embroidery project.

However, if it still feels overwhelming or if you want perfectly digitized results without the learning curve, getting help from a professional is a smart choice. At ZDigitizing, we specialize in hat and cap digitizing. Our expert team from around the world carefully prepares each file based on the type of hat, fabric, and embroidery machine you use.

We guarantee high-quality results, provide 24/7 customer support, offer super-fast turnaround times, and our pricing is lower than most in the market. To help you get started easily, we also offer 50% off your first order so you can test our service with confidence.

Contact us today to get your hat design professionally digitized. Let us take care of the technical work so you can focus on creating amazing embroidered caps.

FAQs

Cap embroidery is the process of stitching logos or designs onto hats using an embroidery machine. It requires special digitizing due to the hat’s curved and structured surface.

It can be tricky at first, especially for curved surfaces like hats, but with practice and good software, it becomes easier. Many beginners use professional services to get started.

Yes, it’s very profitable. Custom caps are in high demand for brands, teams, and events, and they offer great margins even on small orders.

Digitizing for cap embroidery involves a few special techniques:

- Always start stitching from the center of the design and work outward

- Use proper pull compensation to prevent distortion

- Apply knockdown stitching for foam caps

- Simplify the design to fit within the limited embroidery area

- Test stitch on a sample cap to make final adjustments

- Save the design in the correct format supported by your machine