Printing your own custom zip up hoodies is easier than you think! Whether you’re creating for personal use, a group, or promoting your brand, this guide will walk you through the steps to achieve professional results. We’ll cover the two main printing methods—screen printing and direct-to-garment—so you can choose what works best for you.From preparing your design to selecting materials and equipment, we’ll help you every step of the way.

How To Print Custom Zip Up Hoodies

How to Choose the Right Zip-Up Hoodie?

- Fabric Selection: Opt for soft, warm, and durable materials. Cotton, fleece, and their blends are ideal, especially with a cotton content of 80% or higher for maximum comfort and breathability.

- Fit and Style: Decide between a fitted or a loose zip hoodie. Measure your chest, waist, and hips, and match these to the brand’s size chart. The hoodie should be comfortable without being overly snug.

- Color Options: Choose colors that enhance your natural skin tone and hair color, using basic color theory. Seasonal, trendy colors can also keep your style current.

- Quality Inspection: Examine the hoodie’s seams for uniformity and check the fabric dye for colorfastness to prevent bleeding. Ensure that zippers and fittings are robust and functional.

- Versatility: Select a hoodie that suits various settings. Neutral colors offer flexibility, while vibrant shades can create a bold fashion statement.

- Comfort Features: Check for a soft lining and a fabric that’s gentle on the skin. The material should be pleasant to the touch.

- Intended Use: Consider the hoodie’s purpose, whether it’s for casual wear, exercise, or relaxation at home. Different styles may cater to specific activities better.

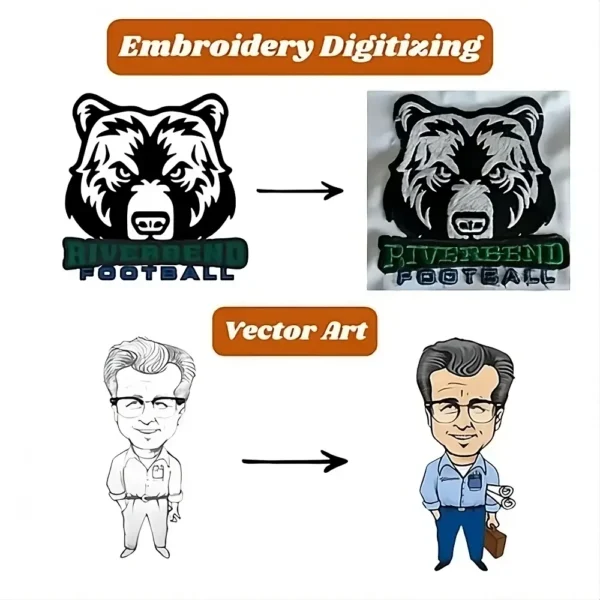

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

2 Main Methods for Printing Custom Zip Up Hoodies

Now your hoodie is properly ready for printing. Let’s see the method suitable for making custom hoodie zip up. It usually depends on your design material or budget.

Method # 1: Screen Printing

The first method for printing on a hoodie is screen printing. It is usually used for bulk orders. Before jumping into the procedure, let’s see which material for screen printing we need:

Materials Required for Screen Printing

- Screen: Used to transfer ink onto the fabric. You can buy them from printing suppliers or make your own screen.

- Ink: Ink for printing is specifically designed for the printing process.

- Emulsion: A light-sensitive liquid that is used to make a design on screen.

- Heat Press: Used to transfer ink from the screen to the hoodie.

- Squeegee: For applying ink on the screen.

- Zipper platen: A zipper platen is a special platen that is designed for printing on zip-up hoodies.

- Tape: Used to secure the screen on the platen.

Once you have gathered all of your materials, It’s time to begin the printing process.

Step-by-Step Process for Screen Printing

Here are the steps involved in printing on zip hoodies:

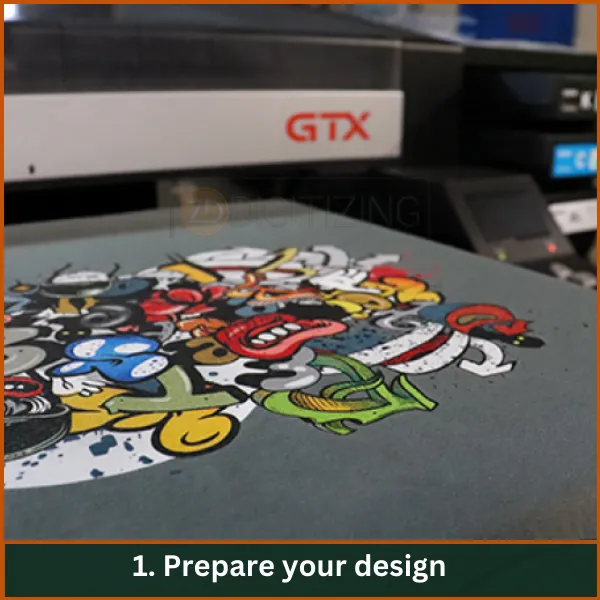

- Prepare your design: Make sure that the design is high resolution and saved in vector format. Also, it should be slightly larger than the desired final print area. Because it may shrink during the printing process. The design should be high-resolution and saved in a vector format.

- Make a screen: To make the screen stretch the mesh screen on the frame. Apply a thin layer of emulsion on the screen. Then place it in the UV light to harden the emulsion. Wash all the unexposed emulsion and let it dry.

- Apply the ink to the screen: Apply the thin and even layer of ink on the screen using a squeegee.

- Transfer the design to the fabric: Place the hoodie on the platen of the heat press and position the screen over the desired design area. Secure the screen in place with tape. Apply heat and pressure to the screen for the amount of time specified by your ink manufacturer.

- Remove the screen and let the hoodie cool: Once the heat press has cooled, remove the screen and let the hoodie cool completely.

Method # 2: Direct-To-Garments (DTG) Printing

The second method is DTG printing, which is used to make custom zip-up hoodies. DTG printing is excellent for detailed and color-rich designs, suitable for small to medium batches. Let’s see what we need to print using the DTG method.

Materials Needed for DTG Printing

DTG Printer: This type of printer is specifically designed for printing on garments.

- Transfer Paper: Transfer paper is a special kind of paper that has a layer of ink on it that can be transferred to the hoodie.

- Heat Press: The ink is moved from the transfer paper to the cloth using a heat press.

- Zip-up Hoodies: Pre-selected hoodies ready for printing

Step-by-Step Process for DTG Printing

Prepare your design: The final design must be digitally saved at a very high resolution. Correct sizing of the design is also important. To prepare for any shrinking in the printing process, the design should be a bit bigger than the desired final print area

Load the design into your DTG printer: Follow the manufacturer’s instructions to load the design into the DTG printer. Ensure that the transfer paper is properly coated and loaded according to the printer’s specifications.

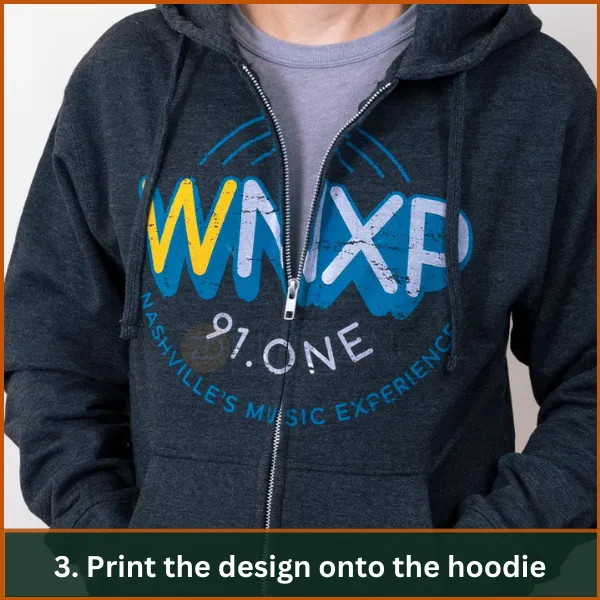

Print the design onto the hoodie: Once your design is loaded, initiate the printing process. The hoodie is placed in the DTG printer, where inks are applied layer by layer directly onto the fabric.

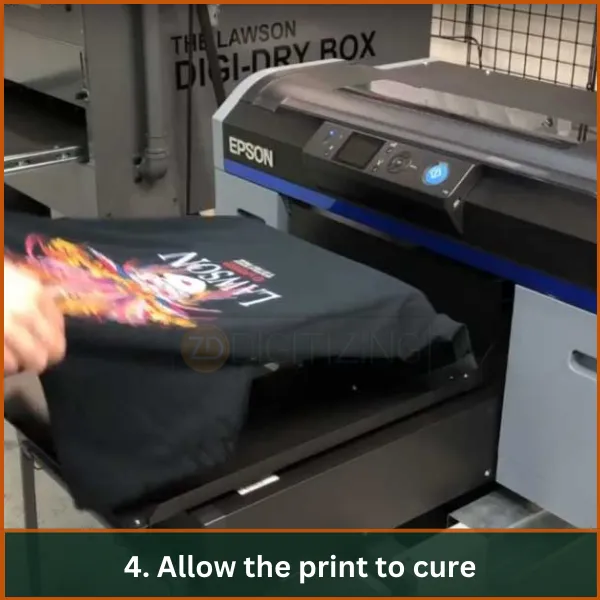

Allow the print to cure: After printing, let the hoodie sit for the transfer paper to fully dry and the ink to set. Curing times can vary based on the printer and ink used

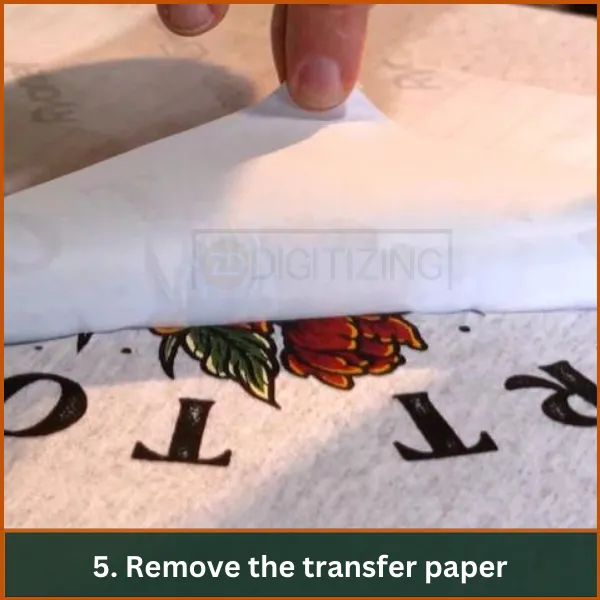

Remove the transfer paper: Carefully peel off the transfer paper once the ink has fully cured. Ensure there are no remnants left on the hoodie.

Common Issues and Solutions for Printing on Custom Zip Up Hoodies

Common Issues | Description | Solutions |

Zipper Ridges | The zipper creates bumps that affect ink coverage and print quality. | Use zipper pallets to reduce the ridges. Design around the zipper to avoid printing directly over it. |

Thick Fabric Challenges | Thick fabrics can cause small shifts in multi-color prints, affecting color alignment. | Use a white base layer on dark fabrics to enhance color visibility. Expect minor shifts during the drying process. |

Double-Lined Hoodies | Extra fabric layers make it hard to fasten the hoodie in place, complicating multi-color prints. | Stick to single-color prints for a simpler and cleaner result. |

Seam Print Mishaps | Printing over seams can disrupt registration and result in unwanted white ink showing through. | Avoid printing directly on seams to keep the design neat. |

Heat Sensitivity | High heat can shrink synthetic fabrics or ruin print quality. | Preshrink garments before printing and use lower heat for longer curing times to prevent issues. |

Ink Buildup | Ink can collect around zippers and seams, creating messy prints. | Keep designs at least 1 inch away from seams to avoid ink buildup. |

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Embroidery Digitizing & Vector Art Services

Looking for embroidery digitizing and vector art services that are affordable and reliable? We offer fast turnaround time, guaranteed quality, and the option to preview your design before payment, we make sure you get exactly what you need. Your satisfaction is our top priority, and we’re dedicated to delivering the best results. Don’t wait—try ZDigitizing today and see the difference in quality and service!

Conclusion: Start Printing Your Own Custom Zip Up Hoodies

We’ve introduced two easy-to-follow methods for printing your own zip-up print hoodies: screen printing and direct-to-garment (DTG) printing.

Both techniques are effective and can be done with the right materials and preparation. Choose the method that works best for you, and start creating your own custom designs at home.

For professional results, you’ll need a high-quality, well-prepared design. That’s where we come in! We offer vector art services at lowest rate possible with fast turnaround time. We also ensure your design is sharp, clean, and ready for printing, guaranteeing the best outcome for your hoodies.

If you’re a first-time customer, we’re offering a 50% discount on your first order! Don’t miss out—reach out to us today and get started on bringing your custom hoodie designs to life.

FAQs

Yes, screen printing is possible on zip-up hoodies. The versatility of screen printing makes it a viable option for decorating a wide range of garments, including zip-up hoodies.

Screen printing is commonly used because it produces long-lasting and bright colors on cloth, making it ideal for hoodies. Heat transfer and direct-to-garment printing are better options if you need detailed designs or a softer feel.

Yes, you can print on hoodies. Just go to our website Zdigitizing and grab our free quote service for design

You’ll need a hot press or screen printing tools to put designs on hoodies. Make your designs on a computer, then use the transfer equipment to put them on heat transfer paper, which you’ll then use to press onto the hoodie’s fabric.

Factors like ink quality and careful washing can extend the life of screen printing on hoodies. If you take good care of your hoodies, the screen printing on them can last for years.