In this comprehensive guide, we will delve into the world of embroidery adhesives, covering everything from the types and application techniques and troubleshooting common problems. Get ready to unlock the secrets of mastering embroidery adhesives without headaches or problems.

How To Really Master In Embroidery Adhesives?

Embroidery adhesives play a crucial role in ensuring successful and flawless machine embroidery projects. Understanding the different types of adhesives available and learning how to use them effectively can greatly enhance your embroidery skills.

Types of Embroidery Adhesives

Let’s have a look at types of embroidery adhesives:

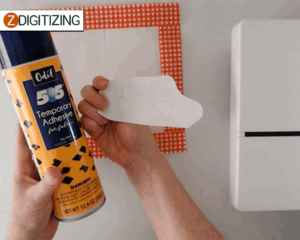

Temporary Embroidery Spray Adhesives:

Temporary adhesive spray is a popular choice for securing fabrics to stabilizers during embroidery. It is typically aerosol-based and provides a temporary bond that can be easily repositioned or removed without leaving residue. This adhesive is suitable for a wide range of fabrics and stabilizers and offers versatility in embroidery projects.

Adhesive Backed Stabilizers:

Adhesive-backed stabilizers have a layer of adhesive applied to one side, making them self-adhesive. They eliminate the need for additional adhesive application, simplifying the embroidery process. Adhesive-backed stabilizers are available in various forms, such as tear-away, cut-away, or wash-away, to accommodate different fabric types and embroidery requirements.

Heat-Activated Adhesives:

Heat-activated adhesives require the application of heat, usually from an iron or heat press, to activate the adhesive properties. These adhesives bond the fabric and stabilizer together when heated, creating a secure bond that remains permanent even after washing. Heat-activated adhesives are often used for appliqué work, as they provide a strong bond for attaching fabric shapes to the base fabric.

Water-Soluble Adhesives:

Water-soluble adhesives are designed to dissolve or wash away with water. They are commonly used for securing small appliqué pieces in place during embroidery. These adhesives provide temporary hold, allowing for precise placement and easy removal once the embroidery is complete.

Fusible Web:

Fusible web is a thin adhesive sheet or tape that can be activated by heat. It is typically used for appliqué work, allowing you to adhere fabric shapes to the base fabric permanently. Fusible web provides a secure bond and helps prevent fraying of fabric edges.

Adhesive Sprays for Appliqué:

Adhesive sprays designed specifically for appliqué work provide a temporary bond between fabric pieces. These sprays allow you to position and adjust fabric shapes before stitching them in place. They offer a strong hold during the embroidery process and can be easily removed or washed away after completing the project.

Embroidery Digitizing

&

Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guaranteed quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

Proper Application Techniques

Proper application techniques are crucial for achieving successful results with embroidery adhesives. Here are some detailed tips and techniques to help you apply adhesives effectively:

Preparing Fabrics and Stabilizers:

- Ensure that the fabric and stabilizer are clean and free from dust, lint, and wrinkles. Iron the fabric and stabilizer if necessary to create a smooth surface.

- If using adhesive-backed stabilizers, remove the release paper from the stabilizer, exposing the adhesive side.

Applying Temporary Spray Adhesives:

- Hold the can of spray adhesive approximately 6-8 inches away from the fabric or stabilizer. Maintain a consistent distance throughout the application.

- Spray the adhesive in a sweeping motion, covering the desired area evenly. Avoid overspraying, as it can lead to excessive adhesion and potential staining.

- For fabrics with delicate or loose fibers, it’s advisable to test the adhesive on a scrap piece first to ensure it does not discolor or damage the fabric.

Using Adhesive Backed Stabilizers:

- Align the adhesive side of the stabilizer with the fabric, ensuring that the adhesive area covers the intended embroidery area.

- Smooth the stabilizer onto the fabric, starting from the center and working outward to remove any air bubbles or wrinkles.

- Use a roller or your hand to firmly press the adhesive-backed stabilizer onto the fabric, ensuring proper adhesion.

Activating Heat-Activated Adhesives:

- Place the heat-activated adhesive on the fabric or stabilizer, ensuring it covers the intended embroidery area.

- Follow the manufacturer’s instructions for activating the adhesive. This may involve using an iron, heat press, or other heat sources.

- Apply heat evenly and avoid excessive heat or prolonged contact to prevent fabric damage. Use a pressing cloth or silicone sheet between the fabric and the iron to protect delicate fabrics.

Securing Appliqué Pieces with Water-Soluble Adhesives:

- Apply small dots or lines of water-soluble adhesive on the back of the appliqué fabric or stabilizer where it will be positioned.

- Carefully place the appliqué piece onto the fabric or stabilizer, aligning it with the embroidery design.

- Gently press the appliqué piece to ensure proper adhesion without distorting the fabric.

Removing Excess Adhesive:

- If you accidentally apply too much adhesive or notice excess adhesive seeping through the fabric, use a clean cloth or cotton swab lightly moistened with a suitable adhesive remover.

- Gently blot the excess adhesive without rubbing, being careful not to spread it further or damage the fabric.

Remember to refer to the specific instructions provided by the adhesive manufacturer for best results and to tailor your application techniques based on the unique requirements of each project. Practice and experimentation will help you refine your skills and achieve seamless application of embroidery adhesives.

Troubleshooting Common Adhesive Problems

Troubleshooting common adhesive problems in machine embroidery is essential for overcoming challenges and achieving flawless results. Here are detailed tips to help you address common adhesive issues:

Uneven Adhesive Application:

Ensure that you hold the spray adhesive can or nozzle at a consistent distance from the fabric or stabilizer throughout the application process.

- Use a steady, sweeping motion while spraying to achieve even coverage.

Pay close attention to the edges and corners of the embroidery area to ensure adequate adhesive application.

Adhesive Not Holding Fabric Securely:

- Double-check that you have applied enough adhesive to create a strong bond between the fabric and the stabilizer.

- Ensure that the fabric and stabilizer are clean and free from any residue or oils that could affect adhesion.

- Allow sufficient drying time as recommended by the adhesive manufacturer before proceeding with embroidery.

Excessive Adhesion:

- If you find that the adhesive is too strong or causing excessive adhesion, reduce the amount of adhesive applied in the affected area.

- Adjust the distance between the spray adhesive can or nozzle and the fabric to control the amount of adhesive being applied.

- Consider using a milder adhesive formula that provides sufficient adhesion without being overpowering.

Adhesive Transferring to the Needle:

- Clean the embroidery needle regularly during stitching to remove any adhesive buildup.

- Use a lint-free cloth or a small amount of adhesive remover to gently remove adhesive residue from the needle.

- Monitor the stitching process closely to ensure that the adhesive is not accumulating on the needle.

Residue or Stains on Fabric:

- If adhesive residue or stains are left on the fabric after embroidery, gently dab a small amount of adhesive remover on a clean cloth or cotton swab.

- Blot the affected area carefully, being mindful not to spread the residue further.

- Test the adhesive remover on a scrap piece of fabric first to ensure it does not damage or discolor the fabric.

Insufficient Washability:

- If your project requires washing after embroidery, ensure that the adhesive used is suitable for laundering.

- Select an adhesive that is labeled as washable and follows the care instructions provided by the adhesive manufacturer.

- Test the washability of the adhesive on a sample piece before washing the entire embroidered item.

By implementing these troubleshooting techniques, you can address common adhesive problems and achieve optimal results in your machine embroidery projects. Remember to adjust your techniques based on the specific adhesive being used and follow the manufacturer’s instructions for best outcomes.

Conclusion:

Mastering embroidery adhesives is an essential skill for achieving professional-looking results in machine embroidery. By understanding the various types of adhesives available, selecting the right adhesive for your project, and mastering proper application techniques, you can overcome common problems and ensure seamless embroidery every time. Remember, practice makes perfect, so experiment with different adhesives and techniques to find what works best for your specific projects. With this comprehensive guide as your resource, you are well-equipped to tackle any embroidery challenge with confidence and achieve remarkable results without the headaches or problems associated with adhesives.

Hope it will be helpful for you guys!

If there’s any question related to this article you can simply ask in the comment section and don’t forget to like and share with those you think might be helpful for them.

Also, if you want digitizing services for your embroidery machine with super-fast turnaround and excellent quality just click the link below and get a free quote in less than 5 minutes. We offer 50% off on all our services to our potential customers.

Frequently Asked Questions

The stabilizer is the foundation of your embroidery and is an essential thing to support your material and thread. Without the use of the right stabilizer the registration of the pattern might be off, you might have puckering, and your material might distort. Your choice of stabilizer could make or break your stitch out.

The common problems of embroidery adhesives are:

- Accidental bonding

- Needle gumming

- Permanent stains

- Sticky workstations

An adhesive in machine embroidery should be used when securing fabric or stabilizer in place during the embroidery process. It is helpful when dealing with slippery or delicate fabrics that need extra stability. Additionally, an adhesive can be used for appliqué or to prevent shifting of layers during embroidery.

While PNGs are able to tackle very high resolutions, they are not infinitely expandable. On the contrary, SVG files are vector-based – built from a complex mathematical network of lines, shapes, dots, and algorithms. They could expand to any size without losing their resolution.