In this article, we will be discussing easy steps for troubleshooting and maintaining the Brother SE 625 embroidery machine. Embroidery machines are complex devices and can encounter issues that may hinder their performance.

It is essential to know how to troubleshoot Brother SE 625 common errors to keep the machine running smoothly. Additionally, regular maintenance is necessary to extend the lifespan of the machine and ensure its continued optimal performance. By following the steps outlined in this article, you can address common issues that may arise and keep your Brother SE 625 embroidery machine in top condition.

Troubleshooting Brother SE 625 Embroidery Machine Common Errors & Solution:

The Brother SE 625 embroidery machine is a versatile and reliable device that can create beautiful and intricate designs on fabric. However, like any machine, it may encounter issues that can affect its performance. Here are some easy steps for troubleshooting Brother SE 625 common errors that may arise with the Brother SE 625 embroidery machine:

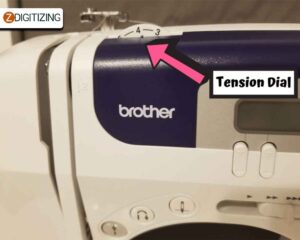

Check The Thread Tension:

If the thread tension is not correct, the machine may not be able to create the desired design. Ensure that the thread is not too tight or too loose. Adjust the tension using the tension knob to get the perfect tension for the specific thread being used.

Check The Needle:

The needle may become dull or bent over time, which can cause stitching issues. Make sure that the needle is the right size for the fabric being used and that it is inserted correctly. Replace the needle regularly to prevent any damage to the fabric.

Check The Bobbin:

The bobbin may not be wound properly, which can cause the machine to skip stitches or create uneven designs. Ensure that the bobbin thread is wound evenly and that the bobbin is inserted correctly into the machine.

Check The Machine Settings:

Incorrect machine settings can cause issues with the design. Check the settings, including the needle position, stitch length, and width, to ensure that they are set correctly.

Use Quality Thread:

Using low-quality thread may cause issues with the design. Ensure that you are using high-quality thread designed for embroidery machines, as this can affect the final result.

Check The Embroidery Design:

The embroidery design may be causing the issue. Check the design to ensure that it is suitable for the fabric being used and that it is correctly digitized.

Restart The Machine:

Sometimes, restarting the machine can resolve issues that may be causing problems with the embroidery design.

Check The Hoop:

Ensure that the fabric is properly hooped and that the hoop is secure. If the hoop is loose, it can cause the fabric to shift during stitching, resulting in an uneven design.

Check The Stabilizer:

The stabilizer is an essential component in embroidery as it helps support the fabric during stitching. Ensure that you are using the correct type of stabilizer for the fabric being used and that it is applied correctly. Incorrect application or the wrong type of stabilizer can cause issues with the design.

Check The Bobbin Case:

The bobbin case may become damaged or misaligned, causing issues with the stitching. Check the bobbin case for any signs of damage, and ensure that it is inserted correctly into the machine.

Check The Tension Spring:

The tension spring can become damaged or misaligned over time, causing issues with the thread tension. Check the tension spring for any signs of damage or misalignment and adjust it as necessary.

Check The Power Supply:

Ensure that the power supply is stable and that there are no issues with the electrical connections. Any issues with the power supply can cause damage to the machine.

These are some easy steps for troubleshooting Brother SE 625 problems & solutions that may arise with the Brother SE 625 embroidery machine. However, regular maintenance is essential to ensure the optimal performance of the machine. Here are some Brother SE 625 maintenance tips that can help extend the lifespan of the Brother SE 625 embroidery machine:

Clean The Machine Regularly:

As mentioned earlier, cleaning the machine regularly is essential to prevent dust and debris from accumulating inside the machine. This can also prevent damage to the delicate parts of the machine.

Oil The Machine:

Oiling the machine regularly can prevent it from overheating and help it run smoothly. Consult the manual for specific instructions on how to oil the machine.

Use The Correct Needle And Thread:

Using the correct needle and thread can prevent damage to the fabric and the machine. Make sure that you are using high-quality thread designed for embroidery machines, and use the correct needle size for the fabric being used.

Store The Machine Properly:

Storing the machine properly can prevent damage to the delicate parts of the machine. Keep the machine covered when not in use, and store it in a dry, cool place.

Replace The Hook And Bobbin Case Regularly:

The hook and bobbin case can become damaged over time, causing issues with the stitching. Replace them regularly to prevent any damage to the fabric or the machine.

Lubricate The Machine:

In addition to oiling the machine, lubricating the moving parts can also help extend the lifespan of the machine. Consult the manual for specific instructions on how to lubricate the machine.

Check The Belts And Pulleys:

The belts and pulleys can become loose or damaged over time, affecting the machine’s performance. Check them regularly for any signs of wear and replace them if necessary.

Keep The Machine Covered:

When not in use, keep the machine covered to prevent dust and debris from settling on the delicate parts of the machine. This can also prevent damage from accidental spills or scratches.

Calibrate The Machine:

Over time, the machine may become misaligned, affecting the accuracy of the designs. Calibrate the machine regularly to ensure that it is stitching accurately.

These are some steps maintaining the Brother SE 625 embroidery machine. By following these steps, you can prevent issues from arising and ensure that the machine continues to perform optimally. Regular maintenance and troubleshooting can also help identify any potential issues early on, preventing any damage to the fabric or the machine. By taking good care of your Brother SE 625 embroidery machine, you can enjoy creating beautiful designs on fabric for many years to come.

Winding up with offer:

We hope this article would be helpful for you. If you want to digitize embroidery design you would need a professional like ZDigitizing, as digitizing is a complex process.

Zdigitizing is a digitizing embroidery company that provides complete digitizing and vector art services all over the world to businesses, industries, and corporations.

So, if you need a digitizing or vector art service for your embroidery machine, with a super-fast turnaround and excellent quality, ZD will be your best choice. Just click the link below and get a free quote in less than 5 minutes. And, get 50% off on your first order.

Hope it will be helpful for you guys!

If there’s any question related to this article you can simply ask in the comment section and don’t forget to share with those you think might be helpful for them.

And finally, thanks for reading!

Frequently Asked Questions

To troubleshoot a Brother SE 625 embroidery machine, start by checking the needle, thread, tension, and hoop. Make sure that they are all properly installed and adjusted. Check the manual for specific instructions on troubleshooting different issues.

To fix common problems with a Brother SE 625 embroidery machine, start by identifying the issue. Common problems include thread breaks, bird’s nests, uneven stitching, and skipped stitches. Check the needle, thread, tension, and hoop and adjust as necessary. Consult the manual or contact customer support for further assistance.

Common problems of the Brother SE 625 embroidery machine include thread breaks, bird’s nests, uneven stitching, skipped stitches, and misaligned designs. These issues can often be caused by improper needle, thread, tension, or hoop settings, or by mechanical issues with the machine. Regular maintenance and troubleshooting can help prevent and fix these problems.