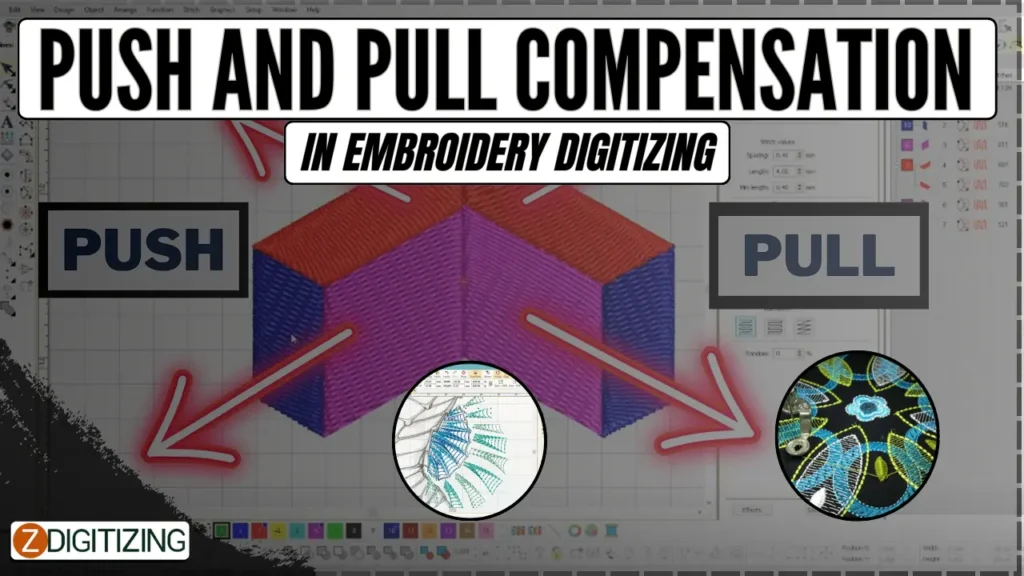

Embroidery digitizing is a meticulous process that involves converting intricate designs into stitch patterns for embroidery machines. One crucial aspect that significantly impacts the final embroidery outcome is push and pull compensation.

Push refers to the fabric being pushed away from the stitching area, while pull refers to the fabric being pulled towards the stitching area during the embroidery process.

Understanding and effectively compensating for these factors are essential to achieve precise and high-quality embroidery results.

In this article, we will explore the concepts of push and pull compensation in embroidery digitizing, their significance, various techniques and tools involved, common challenges faced, and best practices to achieve optimal outcomes.

Push And Pull Compensation In Embroidery Digitizing

What is push and pull compensation?

Push and pull compensation is like the superhero duo of embroidery digitizing. They swoop in to save the day by ensuring that your embroidered designs look fabulous and avoid any mishaps.

In simple terms, its techniques help counteract the natural forces that occur during the stitching process, preventing unwanted distortions and misalignments.

The role of push and pull compensation in embroidery digitizing

Think of these techniques as the secret agents behind the scenes of embroidery digitizing. They work tirelessly to maintain the integrity of your design, ensuring that it translates perfectly from the digital world to the embroidered reality.

By accounting for fabric stretch, thread tension, and other factors, compensation techniques help achieve accuracy, proper stitch formation, and overall design refinement.

Importance of Push and Pull Compensation in Embroidery Digitizing

Let’s see why you need these compensation technique during digitizing embroidery:

Achieving Design Accuracy and Integrity

This is the holy grail for maintaining design accuracy and integrity in embroidery digitizing. By counteracting the forces that threaten to disrupt your design, you can ensure that every detail stays true to the original artwork.

This is particularly vital when dealing with intricate or complex designs that require precise placement and stitch formation.

Ensuring proper stitch formation and density

Proper stitch formation and density are the bread and butter of amazing embroidery. Push and pull compensation techniques play a key role in achieving these essentials.

By accounting for fabric characteristics and adjusting stitch settings, you can ensure that your embroidery has consistent and even stitch lengths, avoiding gaps or bunching. This attention to detail elevates your embroidery from average to exceptional.

Minimizing distortion and misalignment

Nobody likes a crooked or distorted design, especially on a meticulously embroidered piece. These compensation techniques come to the rescue, minimizing distortion and misalignment.

By strategically adjusting stitches, tension, and registration points, you can prevent unwanted stretching, warping, or shifts in your design. The result? A picture-perfect embroidery that stays true to your original vision.

Techniques and tools for Push and Pull Compensation in embroidery digitizing

Embroidery designs can truly come to life when the right techniques and strategies are employed. Here are some key factors to consider when aiming for flawless embroidery designs:

Manual approaches for Push and Pull Compensation

If you prefer a hands-on approach, manual techniques for these compensations can do the trick. These include adjusting stitch angles, adding underlay stitches for stability, and incorporating compensation stitches to counteract fabric stretch and tension.

It may require some trial and error, but mastering manual compensation techniques can give you greater control over the final outcome.

Embroidery Digitizing & Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guarranted quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

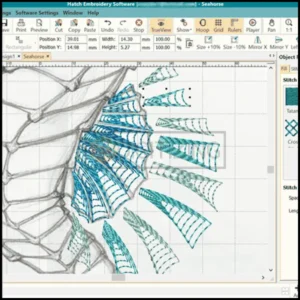

Software-based methods for Push and Pull Compensation

For those who prefer the digital realm, software-based methods offer efficient solutions for push and pull compensation. Embroidery digitizing software often includes features like automatic stitch compensation, pull compensation tools and stitch angle adjustment options.

These tools streamline the process, allowing you to achieve precise compensation without breaking a sweat.

Choosing the right tools for effective compensation

When it comes to push and pull compensation, having the right tools in your embroidery arsenal can make all the difference. Whether you prefer manual techniques or software-based solutions, it’s essential to choose tools that suit your needs, budget, and embroidery goals.

Experiment with different options, seek recommendations and find the perfect combination of techniques and tools that work best for you.

Common challenges and solutions in Push and Pull Compensation

Embroidery designs often encounter push and pull forces, leading to potential distortions or misalignments. Understanding and addressing these challenges can help achieve flawless embroidery results.

Let’s explore some common push and pull compensation problems and their solutions:

Dealing with fabric stretch and shrinkage

Embroidering on different types of fabrics can be a daunting task, especially when they have a tendency to stretch or shrink. This can lead to distorted designs and unsightly results. However, by using push and pull compensation techniques, you can overcome this challenge.

By slightly adjusting the stitch density or direction, you can provide the extra space needed for stretching fabrics or minimize the distortion caused by shrinkage.

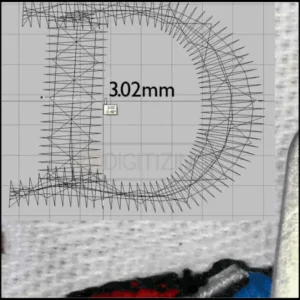

Handling variable fabric thickness

Not all fabrics are created equal when it comes to thickness. Dealing with variable fabric thickness can create inconsistencies in your embroidery, resulting in uneven stitching and puckering.

To tackle this challenge, push and pull compensation can be employed. By adjusting the stitch length or using underlay stitches strategically, you can achieve a smoother and more even finish, regardless of the fabric’s thickness.

Embroidery Digitizing & Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guarranted quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

Addressing stitch distortion and pulling

Stitch distortion and pulling occur when the tension between the fabric and the stitches is uneven. This can lead to unsightly puckering or stretching of the design. These compensation techniques allow you to counteract these issues.

By adjusting the stitch patterns, adding extra stitches in critical areas, or altering the stitch angles, you can ensure that your design remains crisp and distortion-free.

Best practices for achieving High-Quality results with Push and Pull Compensation

Achieving optimal push and pull compensation is like finding the perfect balance between coffee and creamer in your morning brew. Here are some best practices that can help you reach that embroidery nirvana.

Understanding the design and fabric interaction

Before diving into push and pull compensation, it’s crucial to understand how your design interacts with the fabric. Factors such as stitch density, stitch length, and stitch angle can greatly affect the final result.

Take the time to consider the fabric’s characteristics and the intended design outcome to make informed decisions on compensation techniques.

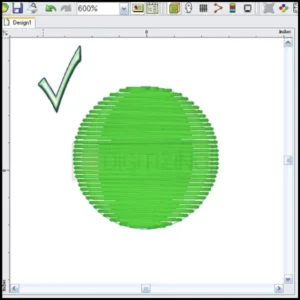

Applying proper stitch types and directions

Choosing the right stitch types and directions can make a world of difference in achieving high-quality embroidery. For example, using a zigzag stitch instead of a straight stitch can provide more flexibility and accommodate fabric stretches.

Additionally, in areas where pulling is a concern, opting for a pull compensation stitch or a different stitch direction can help alleviate the issue.

Testing and adjusting compensation for optimal results

Embroidery digitizing is not an exact science, so it’s important to test and adjust your push and pull compensation techniques for optimal results.

Try different settings, stitch types, and densities on a sample fabric to gauge the impact on the final design. Making adjustments and fine-tuning as necessary will ensure your embroidery looks its best.

Conclusion

In conclusion, push and pull compensation plays a vital role in achieving accurate and high-quality embroidery designs. With an understanding of the concept, the importance of compensation, and the various techniques available, embroidery digitizers can overcome challenges and ensure precise results.

By staying informed and adapting to these future trends, embroidery digitizers can continue to achieve exceptional results and meet the evolving demands of the industry.

ZDigitizing: Your premier choice for embroidery digitizing services

Seeking top-tier embroidery digitizing services? Look no further than ZDigitizing.

We specialize in providing high-quality embroidery digitizing and vector art services to meet all your embroidery and printing requirements, all at highly competitive prices.

Excitingly, we’re currently offering an impressive 50% discount on your first order across all our services. Don’t hesitate to reach out to us.

You can discuss your requirements with us and receive a FREE QUOTE within just 5 minutes.

If you’ve found value in this article, please share it with your friends.

Thank you for reading, and we wish you happy stitching!

Frequently Asked Questions:

The term “compensation” in needlework refers to the adjustment made to stitches to fit a design into a specific space or to counteract fabric distortion.

Stitch compensation in embroidery is the process of adjusting stitch length or density to accommodate fabric stretch or design intricacies, ensuring the final pattern appears as intended.

“Stitch” refers to a single loop or interlocking of thread, while “stitches” is the plural form, indicating multiple such loops or interlocking sequences in embroidery or sewing.

The principle of a stitch involves creating a loop or series of interlocking loops with thread or yarn, which holds fabric or materials together or forms a pattern.

In needlepoint, compensation refers to the adjustment of stitch size or direction to fit a pattern neatly into an irregular area or to maintain pattern integrity on different fabric textures.