When it comes to screen printing, choosing the right white ink is crucial for achieving professional and eye-catching results. Wilflex, a renowned brand in the screen printing industry, offers a range of white inks that cater to various printing needs.

This comprehensive guide aims to provide you with the essential knowledge and insights to choose the perfect Wilflex white ink for your screen printing projects.

So, let’s dive into the world of white ink and discover how to elevate your screen printing game.

Perfect Guide To Choose The Right Wilflex White Ink For Screen Printing

What is Wilflex White Ink?

Wilflex is a brand known for its superior-quality screen printing inks. They provide a wide range of inks, including various types of white inks, each designed for specific fabric types and printing requirements.

Importance of choosing the right White Ink

Choosing the right white ink is crucial for achieving the desired print quality. Whether you’re printing on cotton, polyester, or a blend of fabrics, selecting the appropriate white ink can make or break your design.

The right ink ensures excellent opacity, good coverage, durability, and washability, all while being compatible with the other inks you’re using.

Factors to consider in choosing the right Wilflex White Ink

There are some points you need to consider when selecting ink for printing:

1. Color opacity and coverage

One of the main factors to consider when choosing white ink is its opacity and coverage. You want an ink that provides maximum coverage.

eliminating any color bleed-through from the garment. A highly opaque white ink will make your design stand out, even on darker fabrics.

2. Ink compatibility

Another important factor is ink compatibility. Ensure that your chosen Wilflex White Ink works well with the other inks you plan to use in your design. Compatibility issues can lead to unwanted reactions, affecting the final appearance and quality of your print.

3. Ink Durability and Washability

Durability is key when it comes to screen printing. Look for white inks that offer excellent washability and durability

ensuring that your prints can withstand multiple washes without fading or cracking. Long-lasting prints mean happy customers.

4. Environmental considerations

In today’s eco-conscious world, considering the environmental impact of your printing materials is essential. Look for inks that are environmentally friendly, free from harmful chemicals, and comply with industry standards for sustainability.

Different types of Wilflex White Ink

There are different types of white inks from Wilflex available in the market such as:

1. Water-Based White Inks

Water-based white inks are ideal for a soft, breathable feel on the fabric. They work well on light-colored garments and offer excellent coverage.

Water-based inks are environmentally friendly and have a low impact on the environment.

Embroidery Digitizing & Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guarranted quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

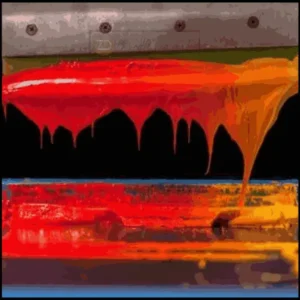

2. Plastisol white inks

Plastisol white inks are more versatile and commonly used in screen printing. They have excellent opacity and coverage.

making them suitable for printing on dark fabrics. Plastisol inks require curing with heat to achieve their full durability.

3. Specialty White Inks

Specialty white inks, such as discharge inks or high-density inks, offer unique effects and textures for your prints.

Discharge inks remove the original fabric color, creating a soft, dyed-in effect, while high-density inks create raised and textured prints. These specialty inks can add an extra dimension to your designs.

Evaluating ink properties for optimal screen printing results

Which properties do you have to check for high-quality printing results:

Viscosity and thixotropy

Viscosity and Thixotropy are essential properties to consider for smooth and consistent printing. Viscosity refers to the ink’s thickness, while thixotropy relates to its flow characteristics when sheared or stirred. Finding the right balance ensures easy printing without clogging or excessive bleeding.

Ink pigments and additives

The choice of ink pigments and additives can impact the final appearance of your print. Consider factors like color vibrancy, lightfastness, and compatibility with other inks.

Additives such as extenders or reducers can help adjust ink properties for optimal printing results.

Curing and drying methods

Curing and drying methods play a crucial role in achieving durable prints. Follow the manufacturer’s instructions to ensure proper curing, whether through heat or air drying.

Properly cured prints will have enhanced washability and longevity.

Little Reminder: Choosing the right white ink involves considering factors like opacity, compatibility, durability, environmental impact, and ink properties.

Selecting the right Wilflex White Ink for different fabric types

Let’s talk about the several kinds of ink that can be used on fabric:

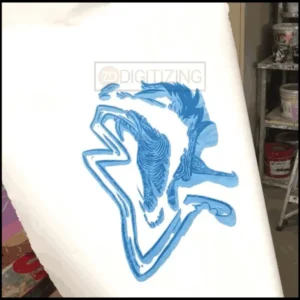

Cotton and cotton blends

When it comes to printing on cotton and cotton blends, you want an ink that can effortlessly glide onto the fabric and provide a smooth, opaque finish. Look for a white ink specifically designed for cotton fabrics.

These inks are formulated to adhere well to the fibers and create vibrant prints that won’t fade after a few washes.

Synthetic fabrics

Synthetic fabrics, like polyester and nylon, can be a bit trickier to print on. The key is to find a white ink that is compatible with these materials.

Look for inks that have good elasticity and can withstand the heat required for curing synthetic fabrics.

This will ensure your prints stay vibrant and durable, even on stretchy workout gear or swimwear.

Dark and Light-Colored fabrics

Printing on dark and light-colored fabrics requires different approaches. For dark fabrics, you’ll need white ink with strong opacity to ensure the design stands out. Look for inks that have good coverage even on dark materials.

On the other hand, for light-colored fabrics, you can opt for a slightly thinner ink that will still provide a bright, crisp print without overpowering the fabric.

Tips for achieving the best results with Wilflex White Ink

There some some tips and tricks that you can follow to achieve the best results:

Proper ink mixing and handling

To achieve the best results with your Wilflex white ink, make sure to follow the manufacturer’s instructions for mixing and handling. Properly mixing the ink ensures consistent color and opacity throughout your prints.

And remember, don’t be too rough with the ink – it’s not a stress ball. Treat it with care and it’ll reward you with fantastic results.

Embroidery Digitizing & Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guarranted quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

Choosing the right screen mesh

The screen mesh you choose can greatly impact the quality of your prints. When using white ink, opt for a screen mesh with a higher thread count for finer details and better ink control.

A higher mesh count will give you sharper prints, like the clarity of your ex’s texts before the breakup.

Proper screen preparation and stenciling

Before diving into the printing process, make sure your screens are properly prepared. Clean them thoroughly and apply a quality emulsion for a clean stencil. A crisp stencil means crisp prints, like freshly folded laundry.

Take your time with the stenciling process and be precise, just like when applying winged eyeliner. You want those lines to be on point!

Troubleshooting common issues with Wilflex White Ink

If you face any issues don’t worry we provide you solutions for them below:

Ink bleeding and smudging

If you notice your prints are bleeding or smudging, it’s time to play detective. Check the ink consistency and make sure it’s not too thin. Adjust your curing temperature and time to ensure the ink fully sets.

And if all else fails, blame it on the weather. Say something like, “Oh, it must be the humidity!” It’s always a safe bet.

Uneven ink coverage

Uneven ink coverage can be a real headache, but fear not!

It’s often caused by improper screen tension. Make sure your screens are properly tensioned to achieve consistent ink coverage.

If you’re unsure, consult a professional or just blame it on ghosts. Who knows what they’re up to in your screen printing studio?

Poor washability and durability

If your prints start to fade after a few washes, it’s time to reassess your ink choice. Ensure you’re using a Wilflex white ink that is specifically formulated for washability and durability.

Follow the recommended curing instructions and use quality additives if needed. And if everything fails, try selling your prints as “vintage-inspired.” It worked for your grandma’s faded t-shirts!

Conclusion: Making the right Choice for perfect screen printing results

Choosing the right Wilflex white ink for your screen printing projects can make all the difference in achieving professional and long-lasting results. Consider the fabric type, color, and desired effect when selecting your ink.

Follow the provided tips and troubleshoot any issues that may arise. With white ink and a little bit of wit and wisdom, you’ll be printing like a pro in no time!

Zdigtizing: Best vector art service provider company at your door

If you’re in search of a reliable vector art service, ZDigitizing is your go-to option. We provide top-notch embroidery digitizing and vector art services at competitive prices.

For new customers, we’re excited to offer a 50% discount on all our services. Take advantage of this deal, talk to us about your requirements, and receive a free estimate within just 5 minutes.

If you have any inquiries, feel free to leave a comment and our team will respond promptly. If you found this information useful, please share it with your friends.

Thank you for reading, and happy stitching!

Frequently Asked Questions:

It is a high-quality ink used in screen printing for its vivid color and opacity, essential for clear prints, especially on dark fabrics.

It typically has a shelf life of about one year; it should be stored in a cool, dry place, away from direct sunlight and extreme temperatures.

Wilflex white inks are developed with environmental considerations, aiming to reduce harmful emissions and waste, but it’s important to follow proper disposal and safety guidelines.

Proper curing of Wilflex white ink requires adhering to the recommended time and temperature guidelines, typically using a heat press or conveyor dryer to ensure durability and color fastness.