The Topic For Today’s Article For Very Interesting “ 10 Tips To Increase Embroidery Production in 2022”

2020 has been a tough time for the business holders and regular workers, and 2021 gives them new hope and a start. Throughout this year, every business is making efforts to grow more and increase its production.

10 tips to increase Embroidery productions in 2022

The embroidery business is one of them struggling so to continue the efficient growth in the coming year these tips for embroidery business persons may help a lot.

Machine downtime may cost you hundreds or even thousands of dollars in delayed profits, and in certain situations, you may lose clients due to your failure to meet their expectations. These small adjustments may significantly speed up your embroidery production with minimum effort and simplify your process.

Here are six simple things to apply immediately with no additional expense to increase your embroidery production in 2022.

1) Before You Begin, Make The Following Plans:

Give enough time for other tasks that will help you avoid problems but are not part of the bordering procedure. For instance, every day, train yourself about the craft. During creation, understanding how particular changes impact certain components saves time and money.

You may become upset and waste time repeating if you see frequent thread breaks due to your ignorance of how tension settings affect the string.

2) Arrange Your Work Area:

Give enough time for other tasks that will help you avoid problems but are not part of the bordering procedure. For instance, every day, train yourself about the craft. During creation, understanding how particular changes impact certain components saves time and money.

You may become upset and waste time repeating if you see frequent thread breaks due to your ignorance of how tension settings affect the string.

3) Get Embroidery Machine Training:

Give enough time for other tasks that will help you avoid problems but are not part of the bordering procedure. For instance, every day, train yourself about the craft. During creation, understanding how particular changes impact certain components saves time and money.

You may become upset and waste time repeating if you see frequent thread breaks due to your ignorance of how tension settings affect the string.

4) Multitasking Is Critical When There Are Fewer Employees:

Start cleaning up post-stick threads and remove stabilizers before placing them on the next clothing or set of garments to ensure a constant flow.

This enables you to comprehend the length of your instructions. This manner, you can correctly estimate production hours and establish deadlines to keep each mission on track.

5) Take Stock Of Your Tensions:

Always correct your tensions when switching thread weights or fabric types. Utilizing a tension gauge accelerates this procedure significantly. Bobbin tension is equally critical since improper bobbin tension results in substandard sewing efficiency and machine downtime.

6) Prepare For Your Upcoming Order:

After you’ve completed your next project and are ready to move on, begin preparing for your next order.For embroidery works, choose the appropriate backing, replace hoops, and do any other job-related tasks. Another excellent time saving is the thread tying in your spare time. Tie the thread for the next order to any needles that are not in use. Don’t remove it.

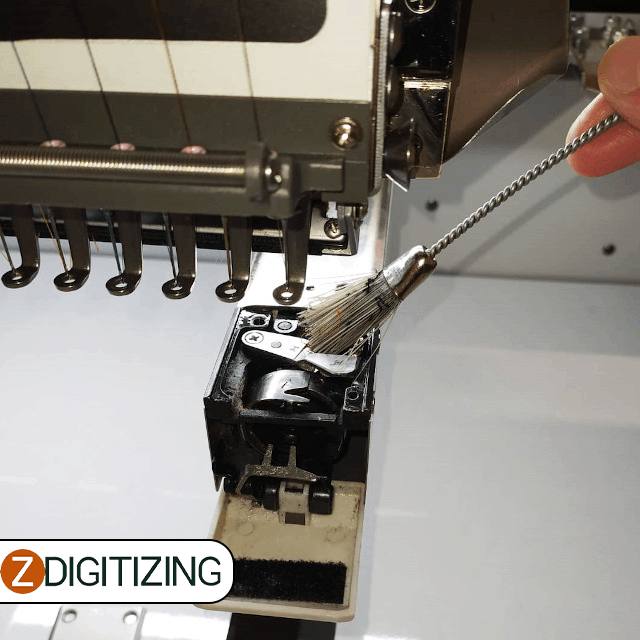

7) Thoroughly Clean Your Machine:

A clean machine operates more efficiently and results in fewer destroyed clothes or caps. Brush away trash and dust regularly, and discard objects that are no longer required.

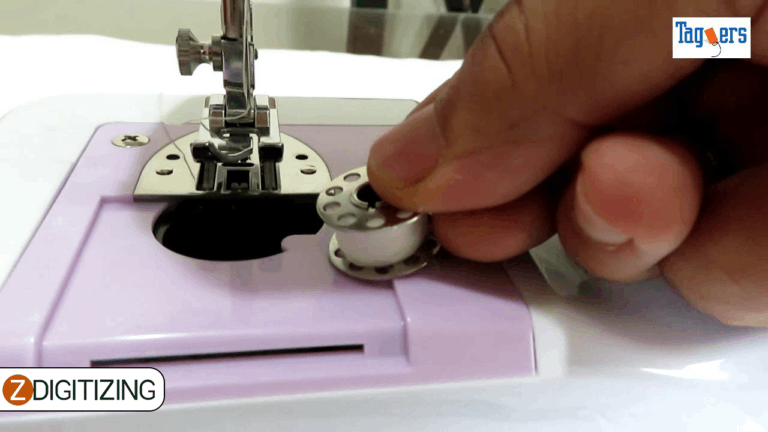

8) Between Rounds, Replace Bobbins

Typically, one bobbin has around 40,000 stitches. Due to the high cost of bobbins, save the old bobbins you remove for orders with a lower stitch count or trial runs. For instance, if you complete a 9,000-stitch order, you should simultaneously change all bobbins between the fourth and fifth production runs.

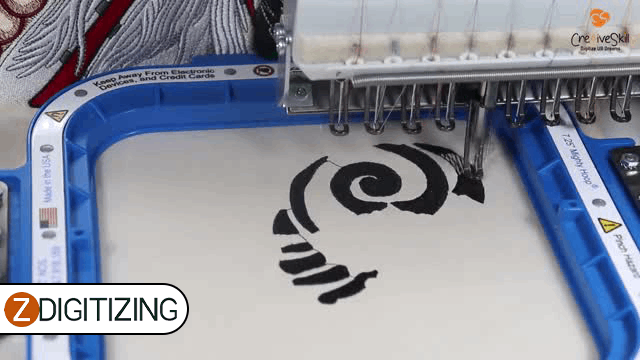

9) Decrease The Speed Of Your Machine For Complex Orders:

Operating your machine at maximum speed is not always the best course of action. In rare instances, digitizing high-quality or intricate logos might be challenging. If you are continuously breaking needles or rethreading, gradually decelerate your machine to find the best stitching pace for your clothing. When utilizing satin stitches, slowing down your machine’s speed can also improve the quality.

10) Increase Production By Purchasing A Multi-Head Embroidery Machine:

On multi-head embroidery machines, you can do far more in a relatively short time. It will cost more in terms of investment, but you may significantly cut labor costs to offset the financial impact of greater computer expenditures.

Conclusion:

When managing an embroidery business, you must meet strict deadlines, which may be stressful and frantic, particularly if you fall behind the competition. Consider devoting a few minutes of your time to implementing these suggestions, and you will see a significant improvement in your production with hardly any extra effort.

We hope this article would be helpful for you. If you want to digitize embroidery design you would need a professional like ZDigitizing, as digitizing is a complex process.

Zdigitizing is a digitizing embroidery company that provides complete digitizing and vector art services all over the world to businesses, industries, and corporations. Zdigitizing provides high-class, durable, and reasonable custom digitizing embroidery and vector art services. We have been delivering top-notch digitizing embroidery services for 20+ years.

So, if you need a digitizing or vector art service for your embroidery machine, with a super-fast turnaround and excellent quality, ZD will be your best choice. Just click the link below and get a free quote in less than 5 minutes.

Hope it will be helpful for you guys!

If there’s any question related to this article you can simply ask in the comment section and don’t forget to share with those you think might be helpful for them.

And finally, thanks for reading!