Hats are one the most widely used items in the World. But we face cap embroidery problems day by day. In this article, we will describe how to solve cap embroidery problems with multi head and single head embroidery machine.

Introduction:

The custom hat embroidery has been enhanced with the expertise of the manufacturer and therefore includes experience. Any error or cap embroidery problem in the custom apparel can trigger a significant loss as you will provide the customer mitering with a minor quality job. For specific cap embroidery problems to be eliminated, some typical digitalization issues of custom hat embroidery should be avoided to achieve the best quality embroidery hats.

Typically, caps are the most challenging thing for embroidery. Therefore, specific crucial questions should be treated cautiously inside the custom hat embroidery, whether the organization is expanding.

Let's Discuss Some Common Cap Embroidery Problems:

Embroidery hooping mistakes:

To begin with, errors are observed in industrial embroidery. But, the first-ever task to do now is to hold the fabric in the embroidery hoop. You can show the point of occurrence where the cap embroidery problem happened in the architecture as you encounter a problem that needs to be resolved.

On the stabilizer of the garment, you will often mark the location right away. The issue typically arises right before the ending stage, supplying you with a design reference point. Leaving the computer running while fixing the issue isn’t always the best option, mainly while using multi-head devices.

Needles Aren't Adjusted Often Enough:

On industrial embroidery devices, there are no rigid and quick guidelines for changing needles. There are many things to remember, including the number of hours the system works, the form of material used, and the needle efficiency. Testing the needles at least once a week and removing them when required, is a healthy routine to establish.

It’s crucial to replace needles regularly, mainly if the timing is off and the needle isn’t going in lockstep with the bobbin case. If a bent needle is not replaced, it will scrape the bobbin case and trigger burrs, fraying and breaking the thread. This continuing concern cuts into manufacturing time and gives rise to the problem of cap embroidery.

Thread tension:

The most famous blunders in industrial embroidery are thread pressure problems. Regularly monitor thread tension to prevent potential cap embroidery problems. Otherwise, the consistency department may be overburdened. Adequate tension, which causes the stitches to be smooth and secure, is often a positive indication of consistency.

The icon and logo clearness could not be affected by the embroidery machine still maintaining the correct thread tension.

Forgetting About Digitizing:

The significant error created in commercial embroidery of caps is forgetting to digitally catch a logo or pattern and ensure that it fits each particular product. Caps and hats are incredibly tricky to embroider on, and file patterns made for flat like T-shirts may create difficulties when used for embroidery. In a curved layer, compensation attached to the surface is distinct from compensation applied to a smooth surface. Where required, a skilled embroidery digitizer can use the data collected for pulling reimbursement for rounded surfaces to be changed. Avoiding these errors would help sustain a reasonable degree of consistency and reduce cap embroidery problems you have to make.

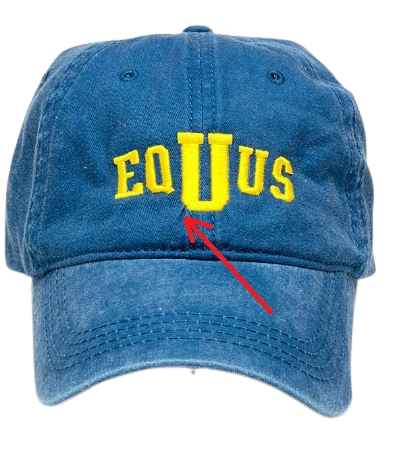

Incorrect Placement of a design:

If customers ask for a lower embroidery design placed next to the price, you can enlarge the design while embroidering a cap. It is relatively popular to wear trendy caps that give the chance to buy new embroidered items. Since the customer does not realize that it is a flawed idea to decorate designs so low on a cap, the design is unlikely to be approved. If a design approach is wrongly applied, it may contribute to inaccurate positioning.

Before assembling the cap, Much of the time, the sewing had been performed on a flat panel application. An experienced embroiderer can work with pieces of fabric or other garments that have already been prepared. To put an embroidery pattern no less than half an inch away from either the front head or sides of the cap is confined to embroidery positioning. And if you somehow manage to capture a needle on the body of the cap or the frame, the computer may likely fail.