In this article we will share some common errors for brother RPE 800 embroidery machine and solutions to solve them.

Brother RPE 800 Embroidery Machine common Errors & Solutions To Maintain

Brother RPE 800 Embroidery Machine Common Errors:

Some common errors that occur on Brother RPE 800 embroidery machine include:

Thread Breakage:

The machine stops working if the thread breaks during embroidery. This can happen if the needle is dull or if the tension is not set correctly.

Needle Breakage:

The needle breaks if it hits a hard object while stitching or if it is bent or damaged.

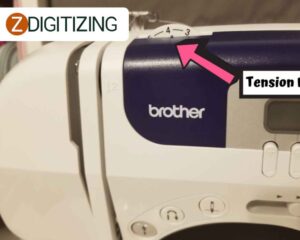

Incorrect Thread Tension:

If the thread tension is not set correctly, the stitches appear loose or uneven.

Skipping Stitches:

The machine skip stitches if the needle is not inserted correctly or if the fabric is not hooped properly.

Machine Jam:

The machine may jam if the fabric or thread gets caught in the mechanism.

Upper Thread Tension Is Too Tight Or Too Loose:

This can cause thread breakage, thread looping, or uneven stitching.

Bobbin Thread Tension Is Too Tight Or Too Loose:

This can cause bobbin thread to show on the top of the fabric or cause looping on the underside of the embroidery.

Machine Not Recognizing The Hoop:

If the machine is not able to recognize the hoop size or type, it may not be able to properly position the embroidery design or may stop working altogether.

Software Or Design File Issues:

Errors can also occur due to issues with the embroidery software or design file. This can cause the machine to stop working or produce an incorrect design.

Motor Or Power Issues:

Sometimes the machine may not turn on or may shut off during operation due to motor or power issues.

If you encounter any of these Brother RPE 800 common errors, refer to the user manual or contact the manufacturer for troubleshooting and repair assistance.

So these were the Brother RPE 800 common errors & solutions. Hope you have understood these common errors brother machine. Let’s move on to Brother RPE 800 maintenance.

Brother PRE 800 Maintenance:

Proper Brother PRE 800 maintenance is essential for ensuring that it performs at its best and has a long lifespan. Here are some Brother RPE 800 embroidery machine maintenance tips to keep your machine in top condition:

Cleaning:

Regular cleaning of the machine is important to prevent dust, lint, and debris from accumulating inside the machine. Use a soft brush or lint roller to remove dust and debris from the machine’s interior and exterior. Clean the bobbin area, the thread path, and the needle plate. Be certain to unplug the machine before cleaning.

Lubrication:

Proper lubrication is necessary to ensure smooth and quiet operation of the machine. Use a high-quality sewing machine oil to lubricate the moving parts of the machine, such as the needle bar, hook race, and bobbin case. Follow the manufacturer’s instructions for lubrication, and do not over-oil the machine.

Bobbin Maintenance:

Check the bobbin case and bobbin for any signs of damage or wear, and replace them if necessary. Make sure the bobbin is correctly inserted in the bobbin case, and that the bobbin case is properly installed in the machine.

Needle Maintenance:

The needle is a critical component of the embroidery machine, and it is important to use the correct type and size of needle for your fabric and embroidery design. Always use a new, sharp needle for each project. Inspect the needle regularly for signs of wear, such as bent or dull tips, and replace as needed.

Thread Maintenance:

Always use high-quality embroidery thread for best results. Check the thread path for any snags or tangles, and re-thread the machine if necessary. Be sure to use the correct thread tension for your embroidery design.

Hoop Maintenance:

The embroidery hoop should be kept clean and free of debris, and checked for signs of damage or wear. Replace the hoop if necessary. Use the correct hoop size for your embroidery design, and make sure the hoop is securely attached to the machine.

Software Updates:

Keep the embroidery software up-to-date to ensure compatibility with the machine and to take advantage of any new features or bug fixes.

Check And Adjust The Tension:

Check the upper and lower thread tensions regularly and adjust as necessary to ensure that the stitches are even and balanced. Refer to the machine’s user manual for instructions on how to adjust the tension.

Check The Feed Dogs:

The feed dogs are the metal teeth that move the fabric through the machine. They can become clogged with lint and debris over time, which can affect the fabric feed. Use a brush or vacuum to remove any lint or debris from the feed dogs and surrounding area.

Clean The Touch Screen:

The touch screen is a critical component of the machine, and it can become dirty or smudged over time. Use a soft, dry cloth to wipe the touch screen clean. Avoid using abrasive or chemical cleaners, which can damage the screen.

Calibrate The Machine:

Calibration is the process of ensuring that the machine is accurately positioned and aligned. This is important for accurate embroidery placement and design size. Refer to the machine’s user manual for instructions on how to calibrate the machine.

Store The Machine Properly:

When the machine is not in use, store it in a dry, clean, and dust-free environment. Cover the Brother RPE 800 embroidery machine with a dust cover to protect it from dirt and any type of debris. Do not expose the machine to direct sunlight or extreme temperatures.

Service The Machine Regularly:

Even with regular maintenance, embroidery machines can develop problems over time. It’s a good idea to have the machine serviced by a qualified technician at least once a year. This could aid identify any possible issues before they become major and costly issues.

By following these Brother RPE 800 maintenance tips, you can help ensure that your Brother PRE 800 embroidery machine runs smoothly and produces high-quality embroidery designs for years to come.

Conclusion:

These were the simple steps for Brother RPE 800 maintenance and troubleshooting Brother RPE 800 embroidery machine. Now that you very well know how to maintain and solve Brother RPE 800 embroidery issues, it is time to start embroidering. Good luck!

We hope this article would be helpful for you. If you want to digitize embroidery design you would need a professional like ZDigitizing, as digitizing is a complex process.

Zdigitizing is a digitizing embroidery company that provides complete digitizing and vector art services all over the world to businesses, industries, and corporations. Zdigitizing provides high-class, durable, and reasonable custom digitizing embroidery and vector art services. We have been delivering top-notch embroidery digitizing services for 20+ years.

So, if you need a digitizing or vector art service for your embroidery machine, with a super-fast turnaround and excellent quality, ZD will be your best choice. Just click the link below and get a free quote in less than 5 minutes. And, get 50% off on your first order.

Hope it will be helpful for you guys!

If there’s any question related to this article you can simply ask in the comment section and don’t forget to share with those you think might be helpful for them.

And finally, thanks for reading!