This article is all about Embroidery machine speed. We will show you why you should not push the speed of your machine to fasten your work, how to have quicker outcomes while maintaining the best quality, and why you should get quality Digitized embroidery for advanced Embroidery designs of the best quality.

Guide To Embroidery Machine Speed For Quality Embroidery Design

Important Factors That Impact Embroidery Machine Speed:

The speed of the embroidery machine matters not just for production but for the design of your embroidery patterns as well. It all depends on whether you are using a home or a commercial machine. You would have a different speed range to select from, but this does not mean that the quality would be the same at all speeds for all kinds of embroidery projects.

The Embroidery machine’s speed is defined by how many stitches it could produce in one minute. Increasing the speed might outcome in bad quality embroidery projects. This is real for complex and colorful machine embroidery designs, for instance, in which case pushing the speed of the machine often outcomes in crunched and puckered embroidery.

1. Fabric Type:

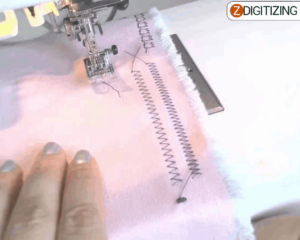

Running on different materials means different speeds for every material. If you are using heavy fabric to embroider like leather or vinyl, you have to slow down your machine. Usually, the quicker the machine goes, the more pull you would have in the tension, which increases the possibility of puckering. This possibility is higher when it comes to very thick or very light materials.

Materials such as nylons, tulles, and silks require gentle handling. A slow operation mode would make less tension while stitching, enabling the fabric to lie more naturally and reducing puckering in your embroidery patterns.

2. Embroidery Type:

Few types of embroidery need less tension to be made on the design, like free-standing lace and embroidery designs with multiple colors and details. In those cases, an extended speed could outcome in an unpredictable piece that falls apart.

Embroidery Digitizing

&

Vector Art Services

Are you looking for embroidery digitizing and vector art services at low cost with superfast turnaround, guaranteed quality and preview before pay? So, you are at right place. We can digitize and vectorize any type of artwork in your required file format.

3. Stitch Width:

One important aspect that would impact the embroidery machine speed is the width of the thread. Thicker threads require slowing down the machine because wider threads make more movement on the frame, and if it becomes wider, the machine would slow down automatically based on the stitch width.

4. Quality And Type Of Thread:

Relying on the type of embroidery threads you are using in your embroidery designs, you might have to adjust the speed of the machine to accommodate the least amount of thread breaks or nesting possible. Polyester threads are more reliable, constant, and tend to break less. On the contrary, rayon thread is an artificial fiber made of wood cellulose, which makes it tough to work with even though it looks pretty.

Cheap threads easily break and the same happens with old or out-of-date threads. Keep in mind, that threads do have a shelf life, they don’t last long in hot, dry, or humid weathers, so have this in mind before placing your threads in an unsuitable place.

5. Machine Type:

A lot of home embroidery machines have an adaptable speed, and all commercial machines could be programmed to fasten or slow down according to production needs and requirements. These adjustments are useful for different embroidery projects that would need different stitching speeds. Some commercial machines accommodate high-speed production with constant quality.

The Key Factor That Impacts Your Embroidery Machine Speed:

Embroidery digitizing is the most important factor that would tell how fast your machine is capable to run. The majority of machines run about 600 to 700 stitches in one minute on average for embroidery designs. If a design has ample color changes and trims, it would take longer for the design to embroider. All these stops slow down the embroidery process.

Using a finely digitized design with no thread breakage makes a huge difference. An expertly digitized design should be production-friendly as it would save you money and time and in the long run, would be capable to recover the money you paid for it if you’re using it numerous times. We very well understand the embroidery issues and solutions for quality embroidery patterns.

Here’s Your Takeaway:

Your embroidery machine speed relies on a lot of factors. You should find the right operatory mode for every embroidery project. And for that, you first need to understand your equipment to get the finest outcomes.

Though, the most important thing is to get good quality machine embroidery designs. This is the only thing you can select that you would remain the same for any embroidery project you are creating and one that would affect the quality of your final product directly as well as your production time and speed. That is the reason embroidery digitizing is so important.

Conclusion:

We hope this article would be helpful for you. If you want to digitize embroidery design you would need a professional like ZDigitizing, as digitizing is a complex process.

Zdigitizing is a digitizing embroidery company that provides complete digitizing and vector art services all over the world to businesses, industries, and corporations. Zdigitizing provides high-class, durable, and reasonable custom digitizing embroidery and vector art services. We have been delivering top-notch digitizing embroidery services for 20+ years.

So, if you need a digitizing or vector art service for your embroidery machine, with a super-fast turnaround and excellent quality, ZD will be your best choice. Just click the link below and get a free quote in less than 5 minutes. And get 50% off on your first order.

Frequently Asked Questions

Embroidery digitizing is the most important factor that would tell how fast your machine is capable to run. The majority of machines run about 600 to 750 stitches in one minute on average for embroidery designs. If a design has ample color changes and trims, it would take longer for the design to embroider. All these stops slow down the embroidery process.

Using a finely digitized design with no thread breakage makes a huge difference. An expertly digitized design should be production-friendly as it would save you money and time and in the long run, would be capable to recover the money you paid for it if you’re using it numerous times. We very well understand the embroidery issues and solutions for quality embroidery patterns.

Your embroidery machine speed relies on a lot of factors. You should find the right operatory mode for every embroidery project. And for that, you first need to understand your equipment to get the finest outcomes.

Though, the most important thing is to get good quality machine embroidery designs. This is the only thing you can select that you would remain the same for any embroidery project you are creating and one that would affect the quality of your final product directly as well as your production time and speed. That is the reason embroidery digitizing is so important.